Brand: KX-Alloy

Similar grades:Alloy42,K94100,42HA(俄), W.Nr. 1.3917

Certification certificate:ISO9001:2015

Place of Origin: Danyang, Jiangsu, China

Alloy Category: Expansion alloy

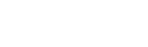

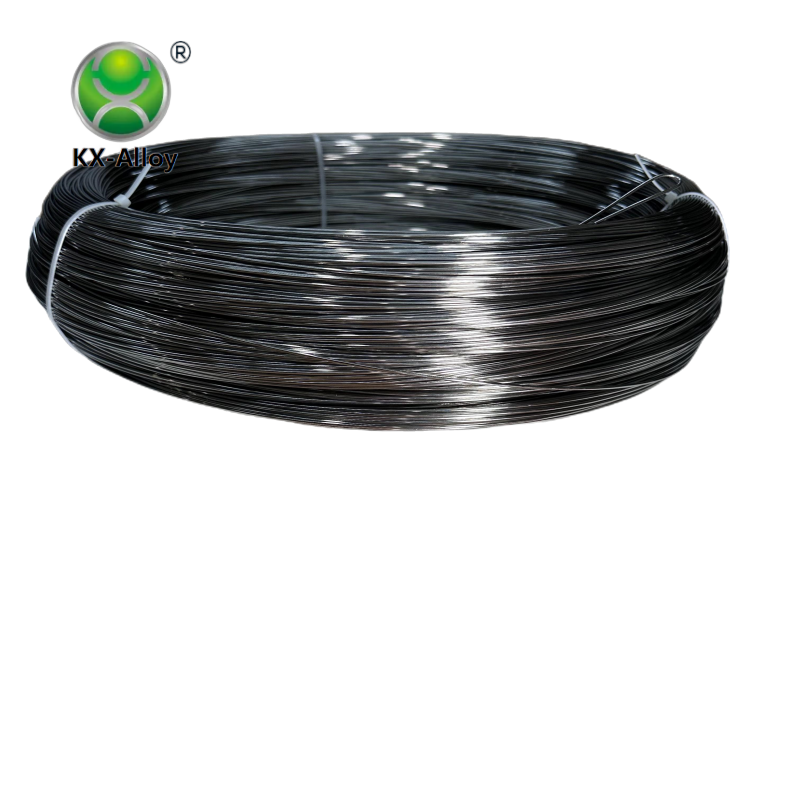

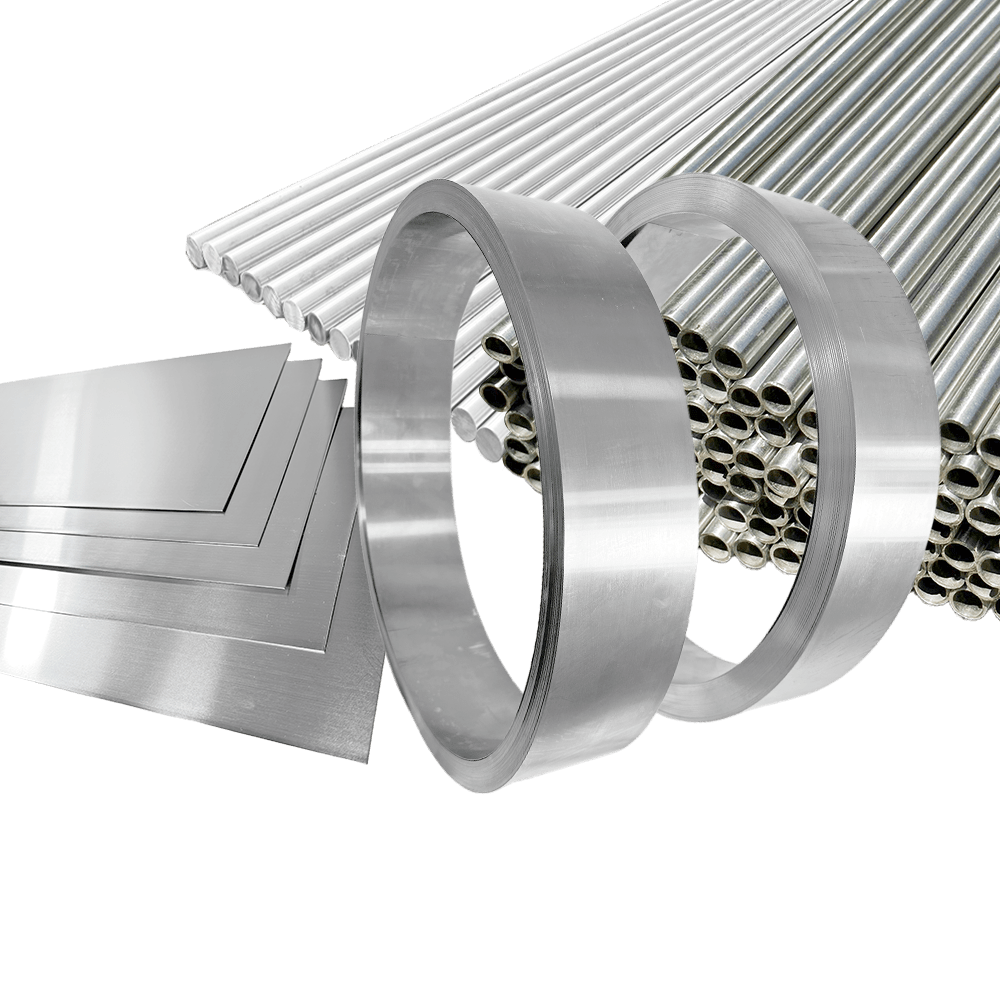

Substrate shape: wire/strip/rod/pipe/plate

Alloy series: nickalloy

Implementation standards:ASTM

Applocation fields: Aerospace,Military industry,Telecommunications, industry, aerospace, Marine