Brand: KX-Alloy

Similar grades:4J32,Alloy32,Super Invar

Certification certificate:ISO9001:2015

Place of Origin: Danyang, Jiangsu, China

Alloy Category:Expansion alloy

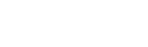

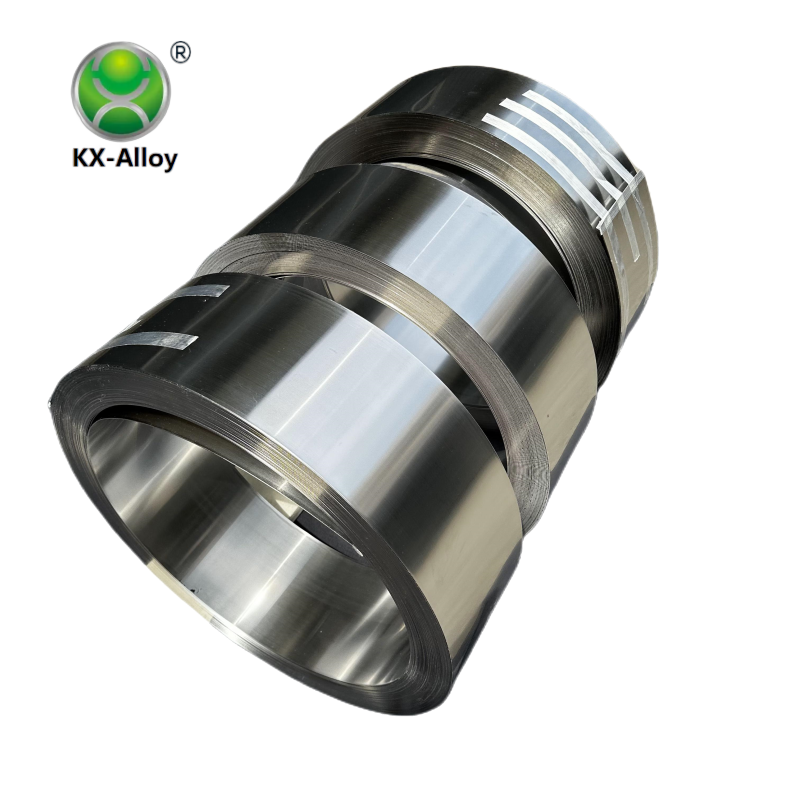

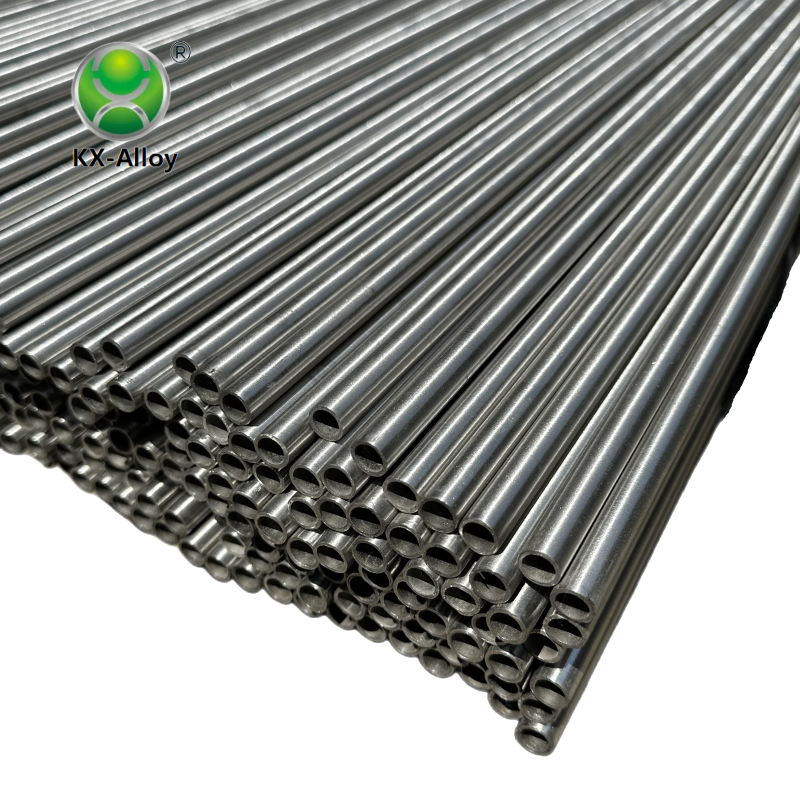

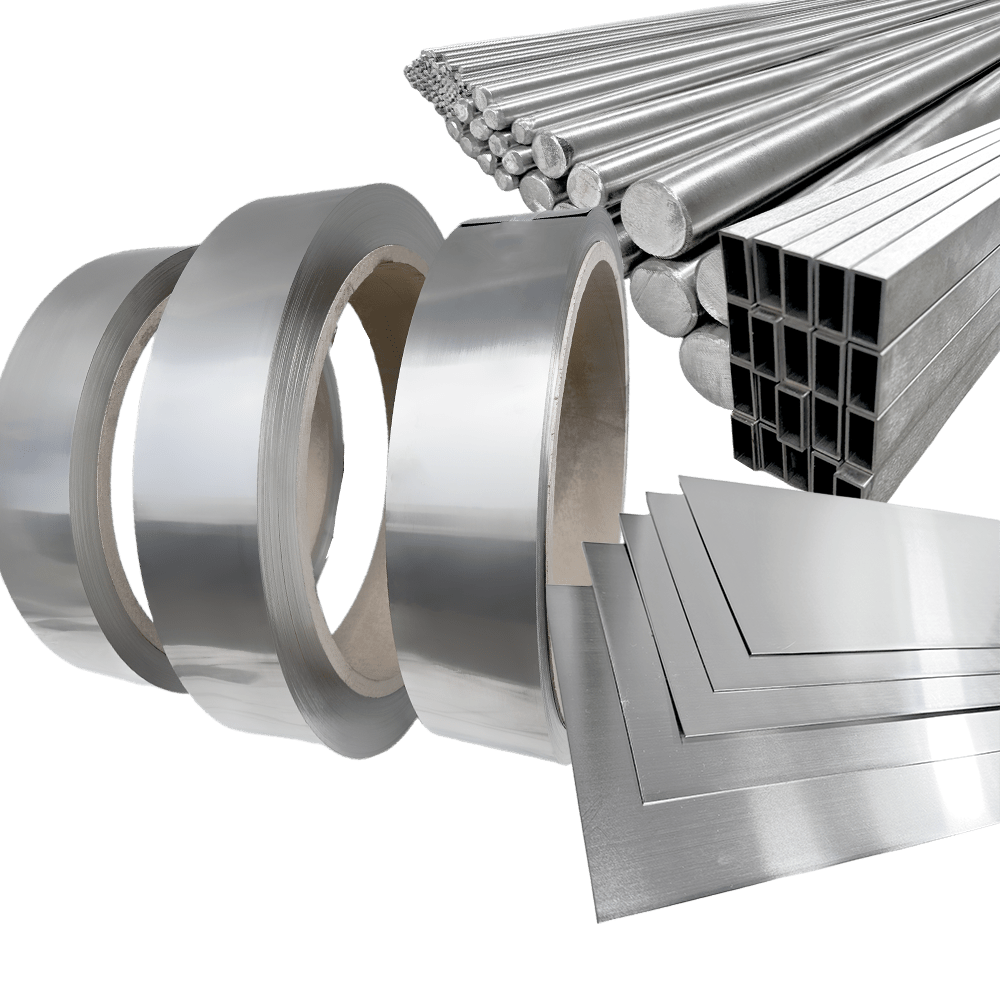

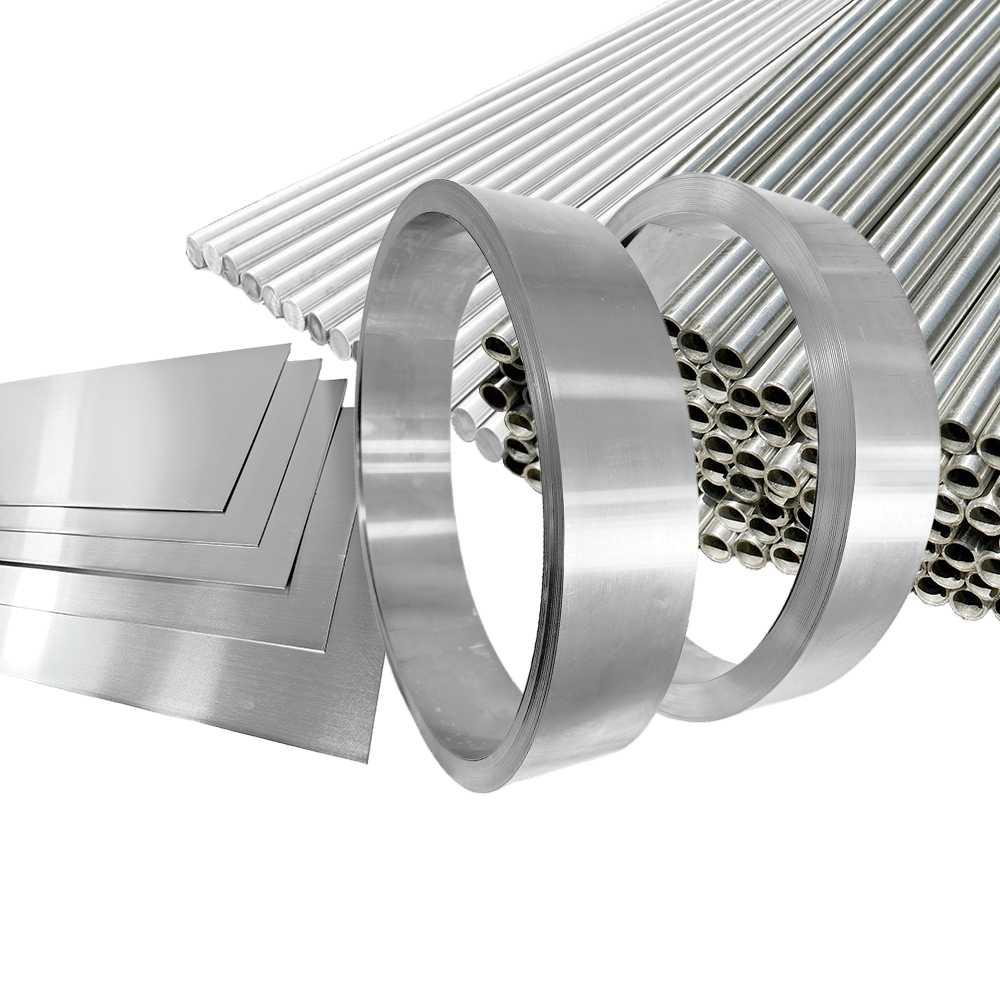

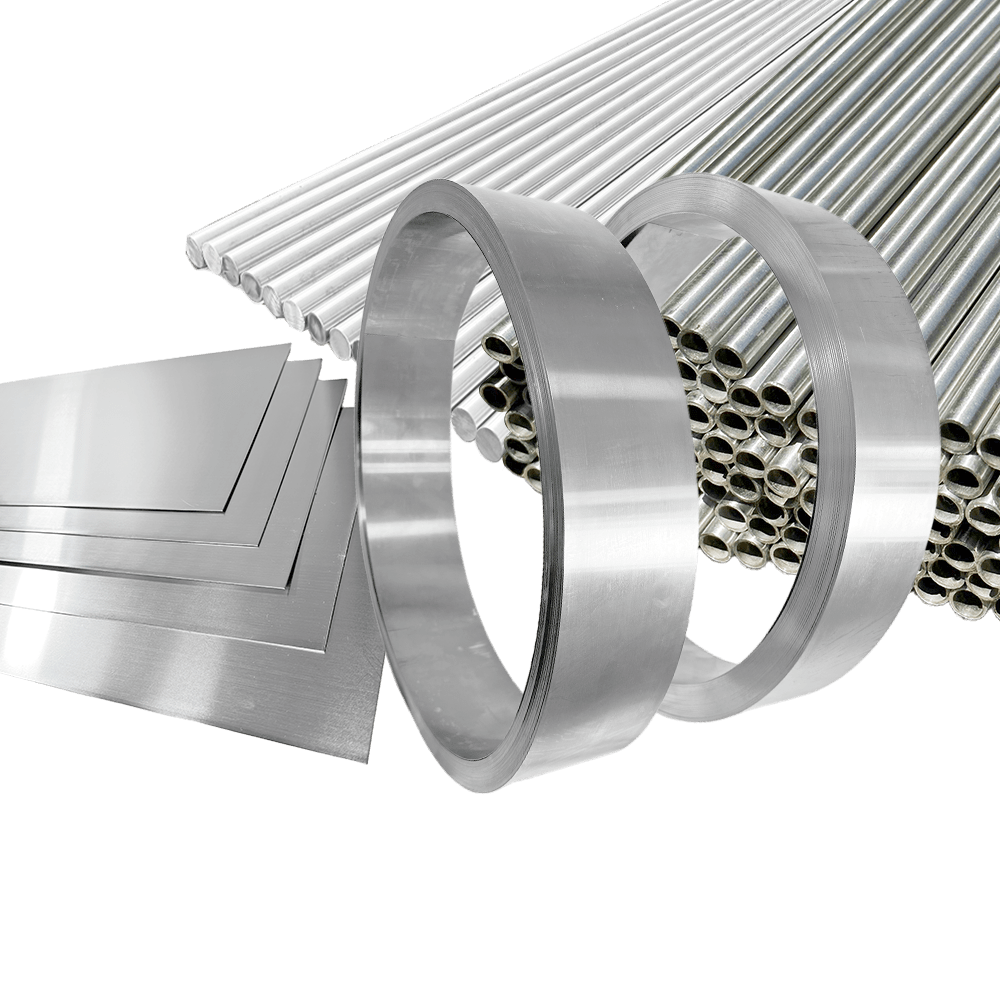

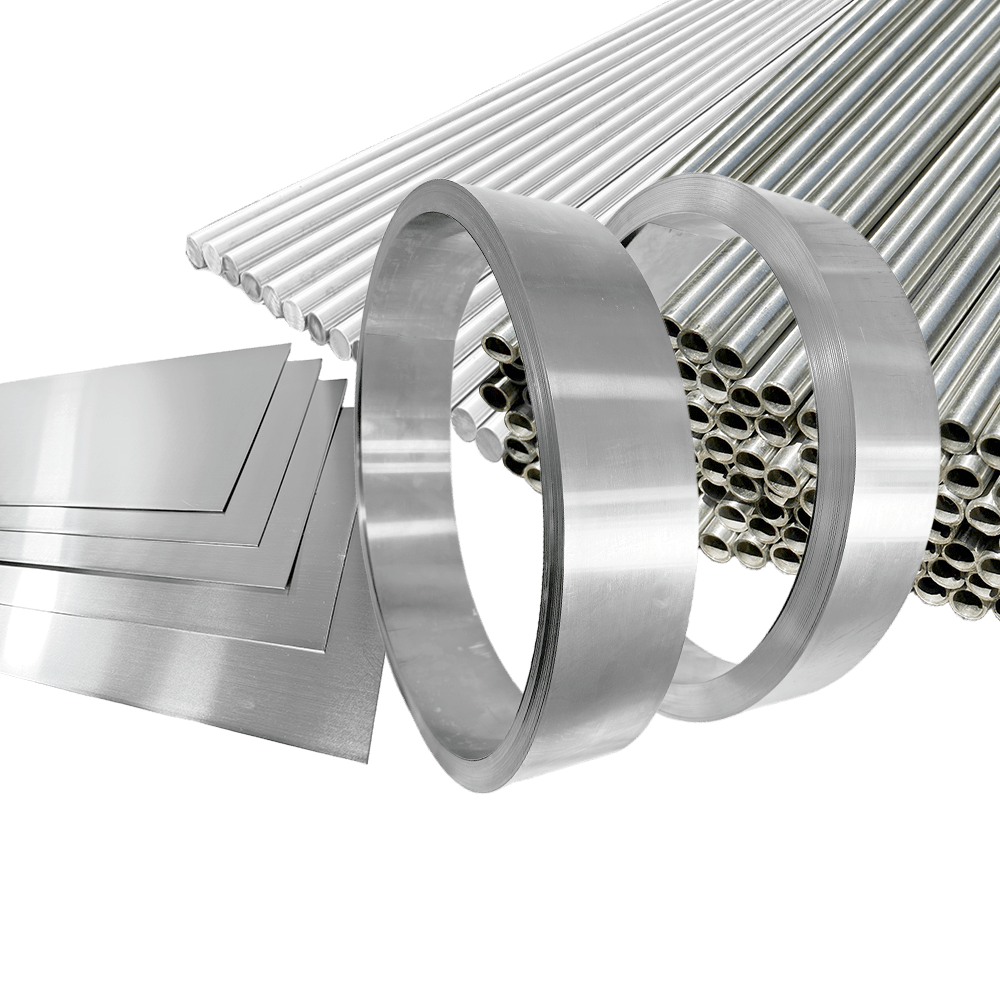

Substrate shape: wire/strip/rod/pipe/plate

Alloy seires:perminvar

Implementation standards:YB/T5241-2005

Applocation fields: Telecommunications, industry, aerospace, Marine