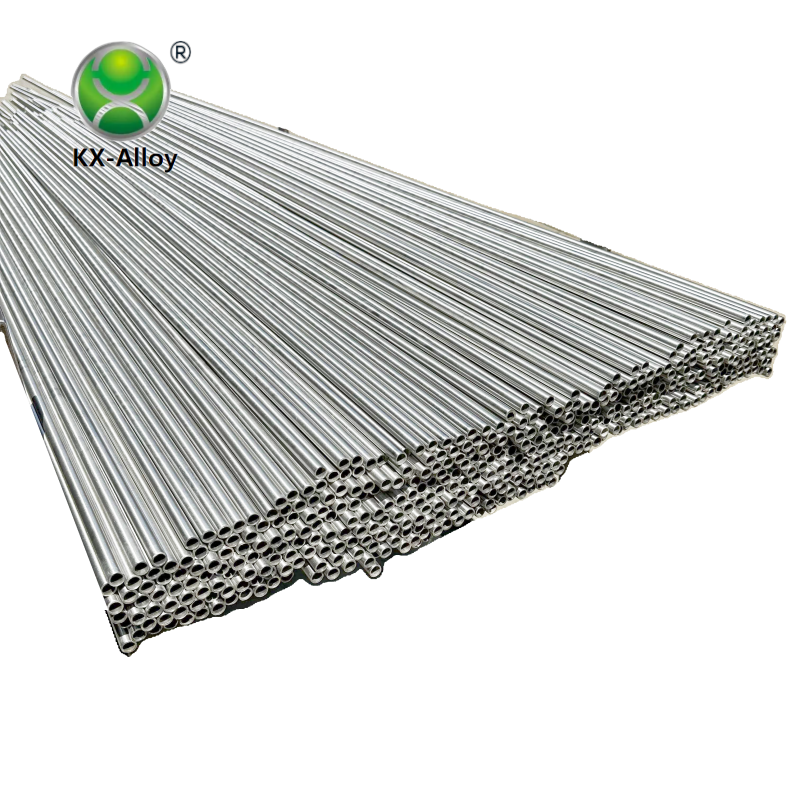

Brand: KX-Alloy

Similar grades: GH4145,NiCr15Fe7TiAl,NC15FeTNbA,NCF750

Certification certificate: ISO9001:2015

Place of Origin: Danyang, Jiangsu, China

Alloy Category: Corrosion Resistant Alloy

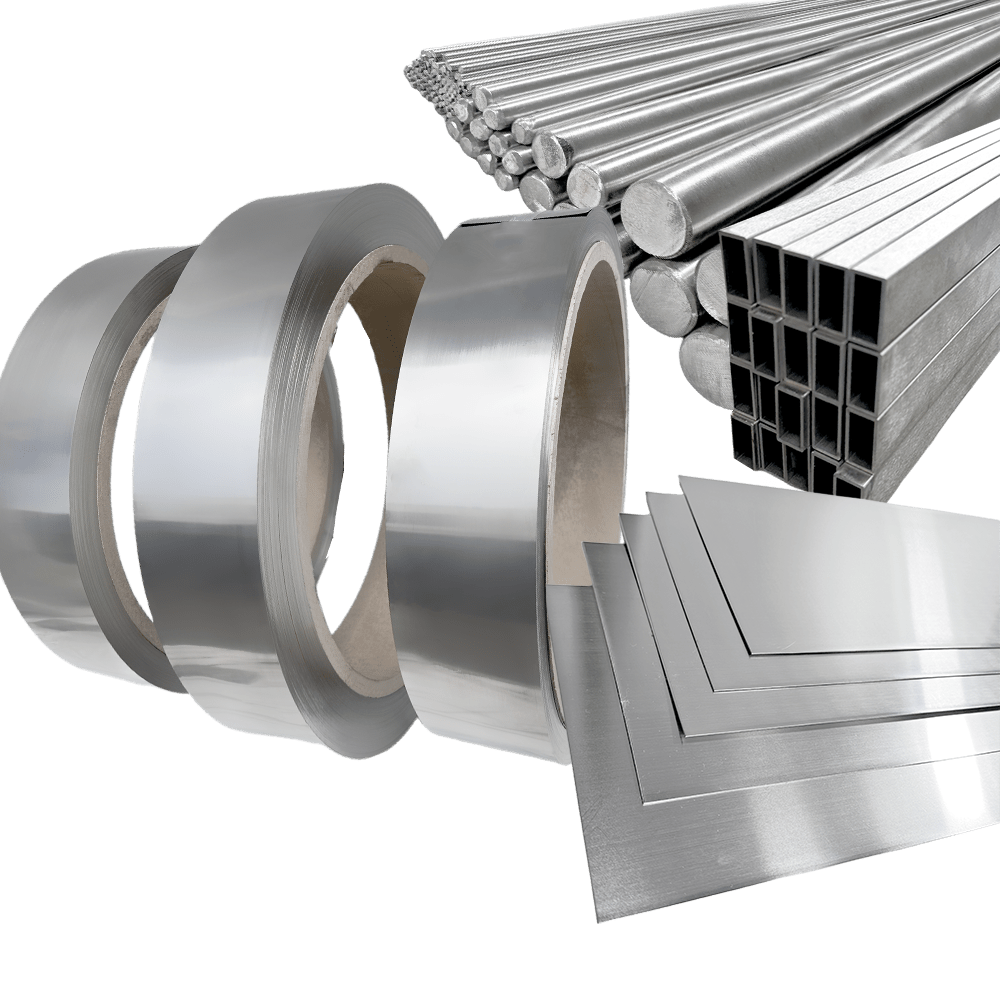

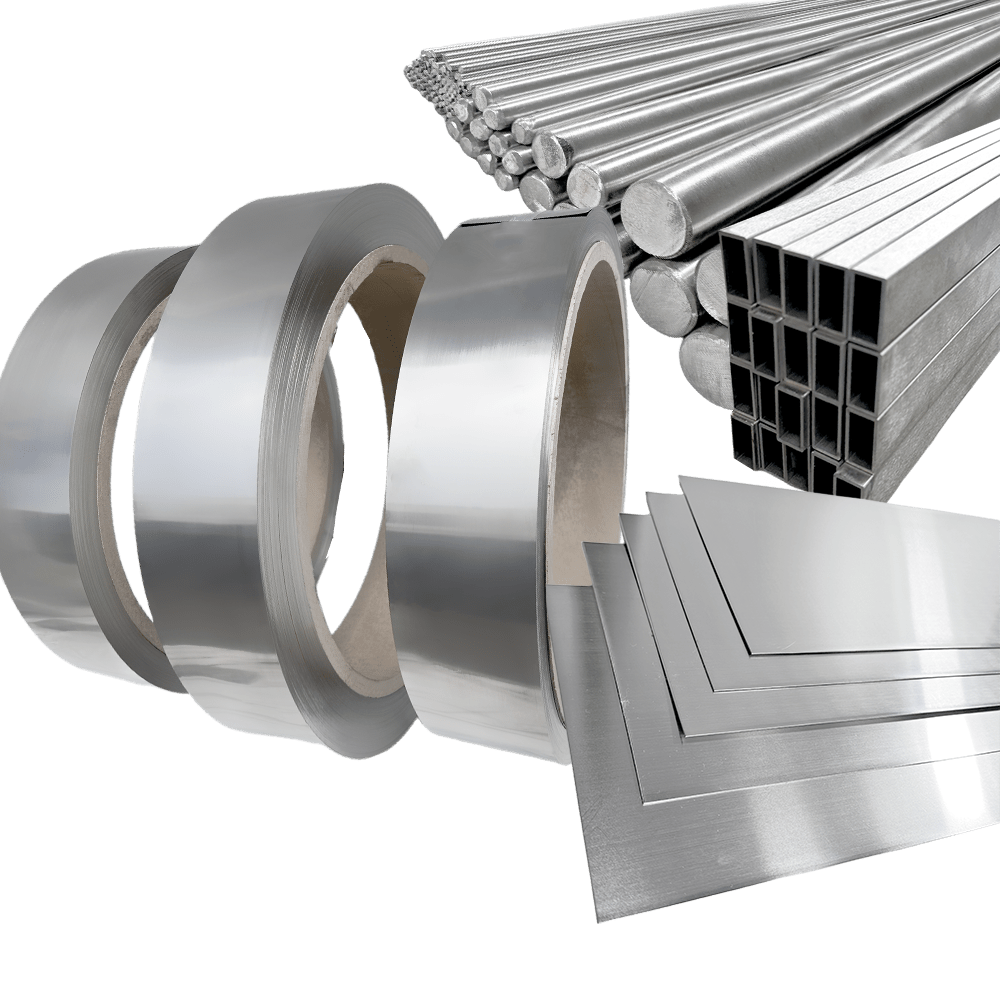

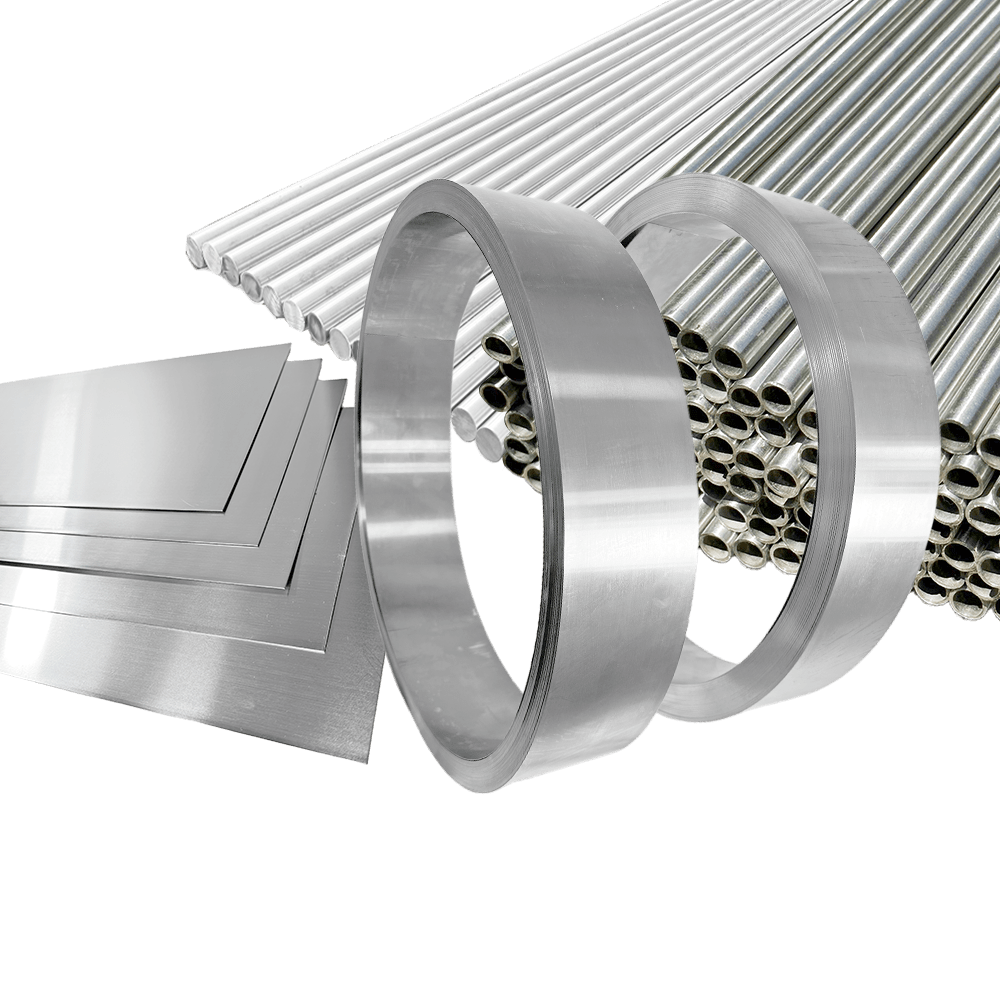

Substrate shape: shaft wire/strip/straight strip

Alloy series: nickel-chromium alloy

Application areas: ASTM B637

Applications: Automotive, petrochemical, energy, aerospace