Brand: KX-Alloy

Approximate brand: UNS N07718 GH4169

Certification certificate: ISO9001:2015

Place of Origin: Danyang, Jiangsu, China

Alloy category: corrosion resistant alloy

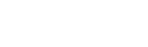

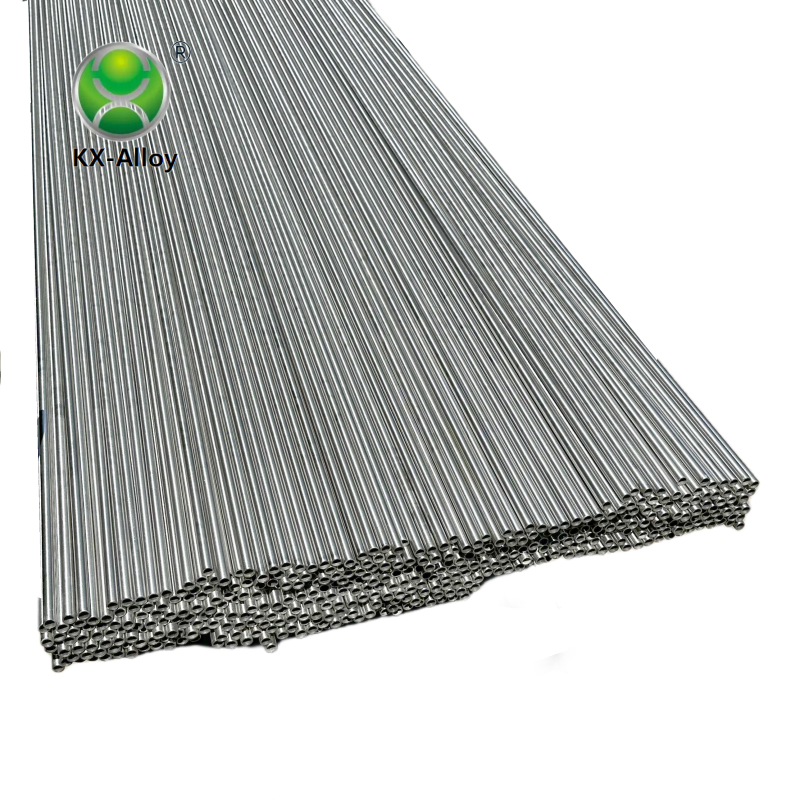

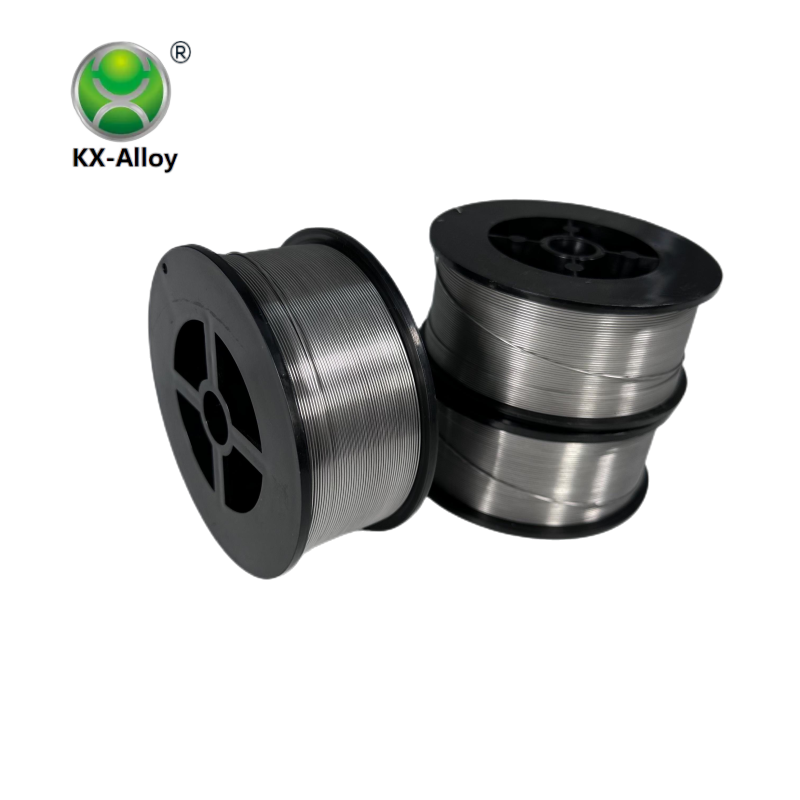

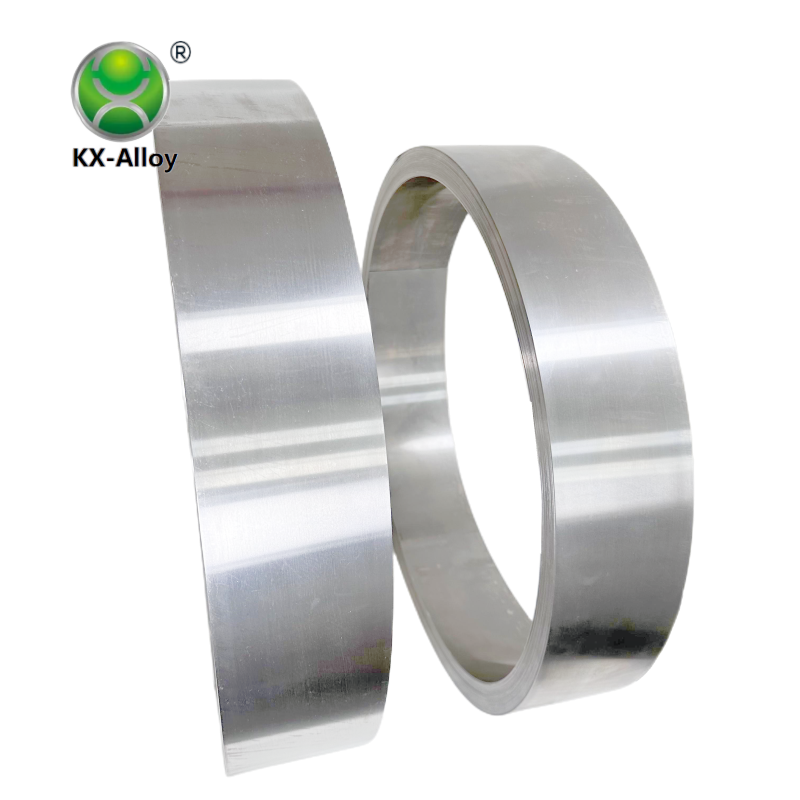

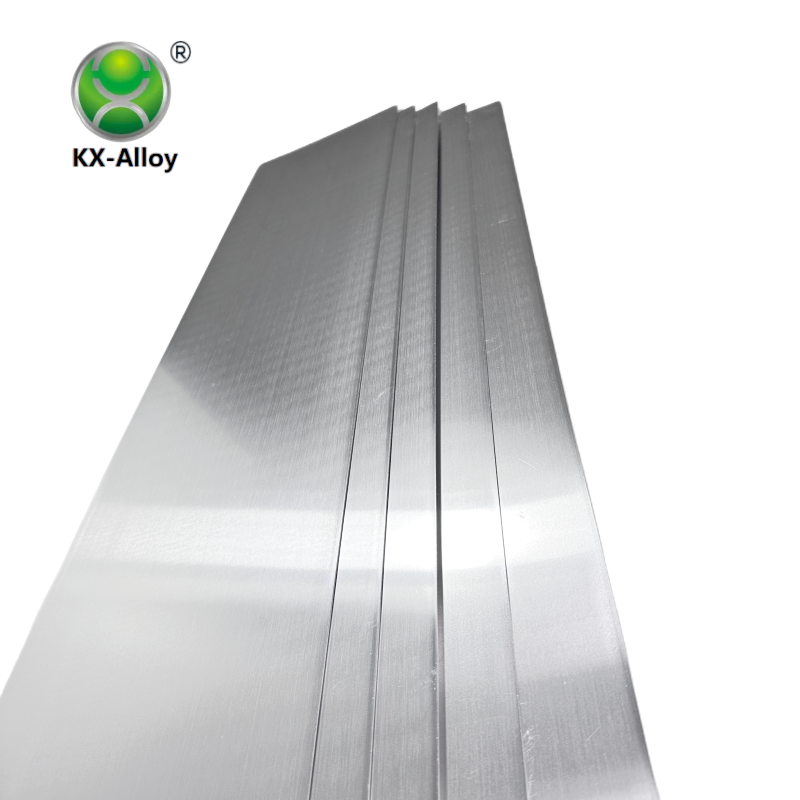

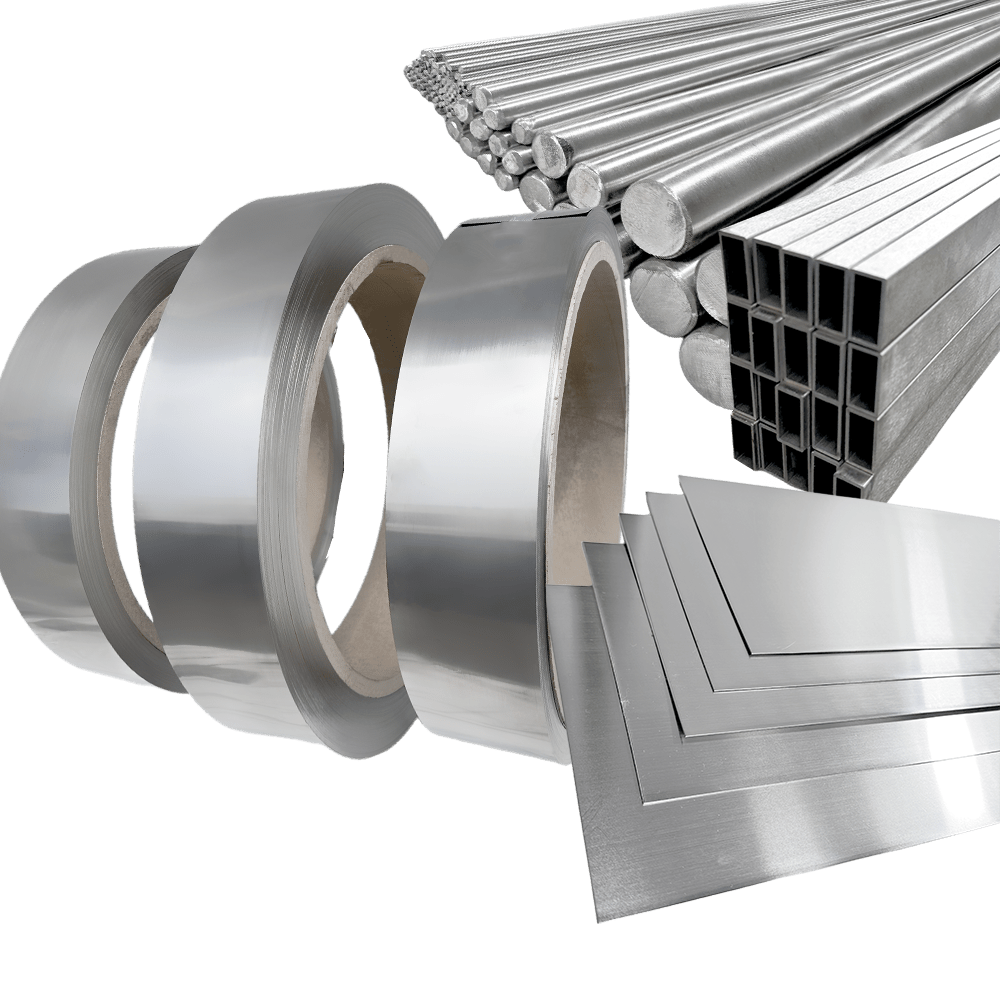

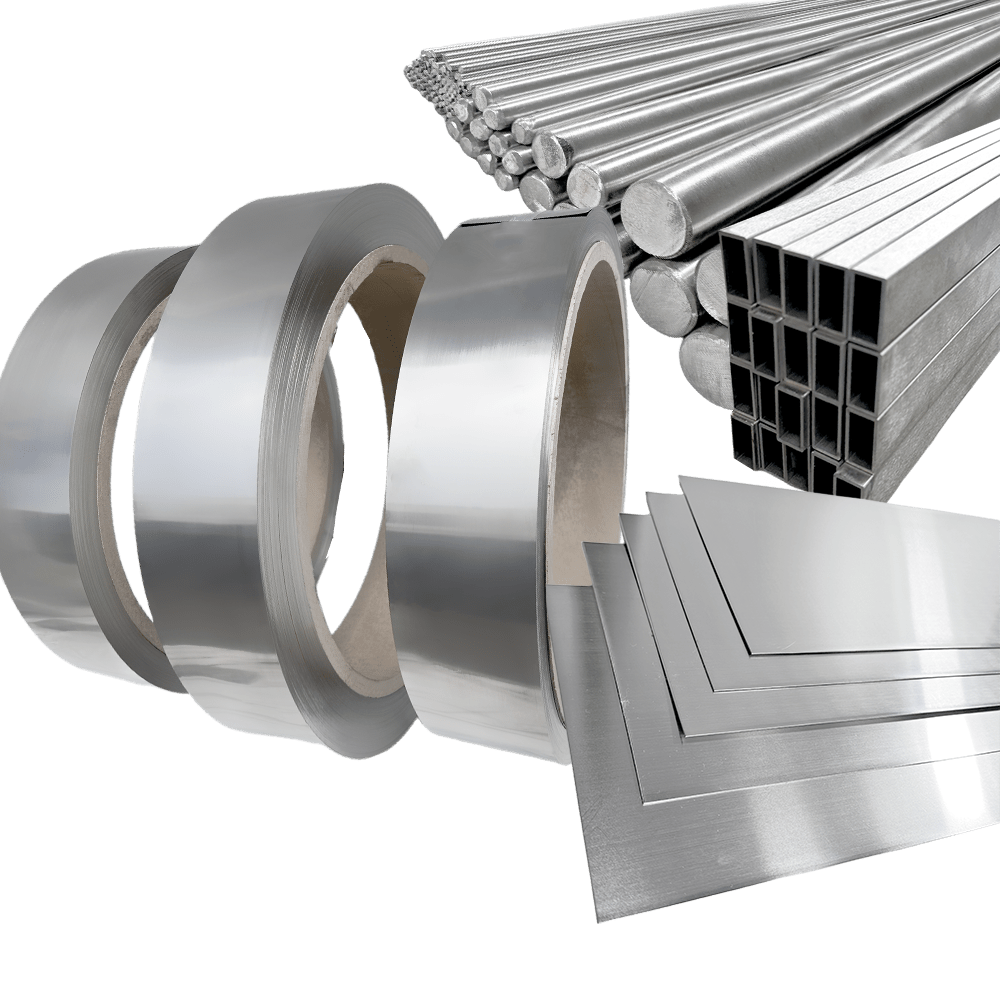

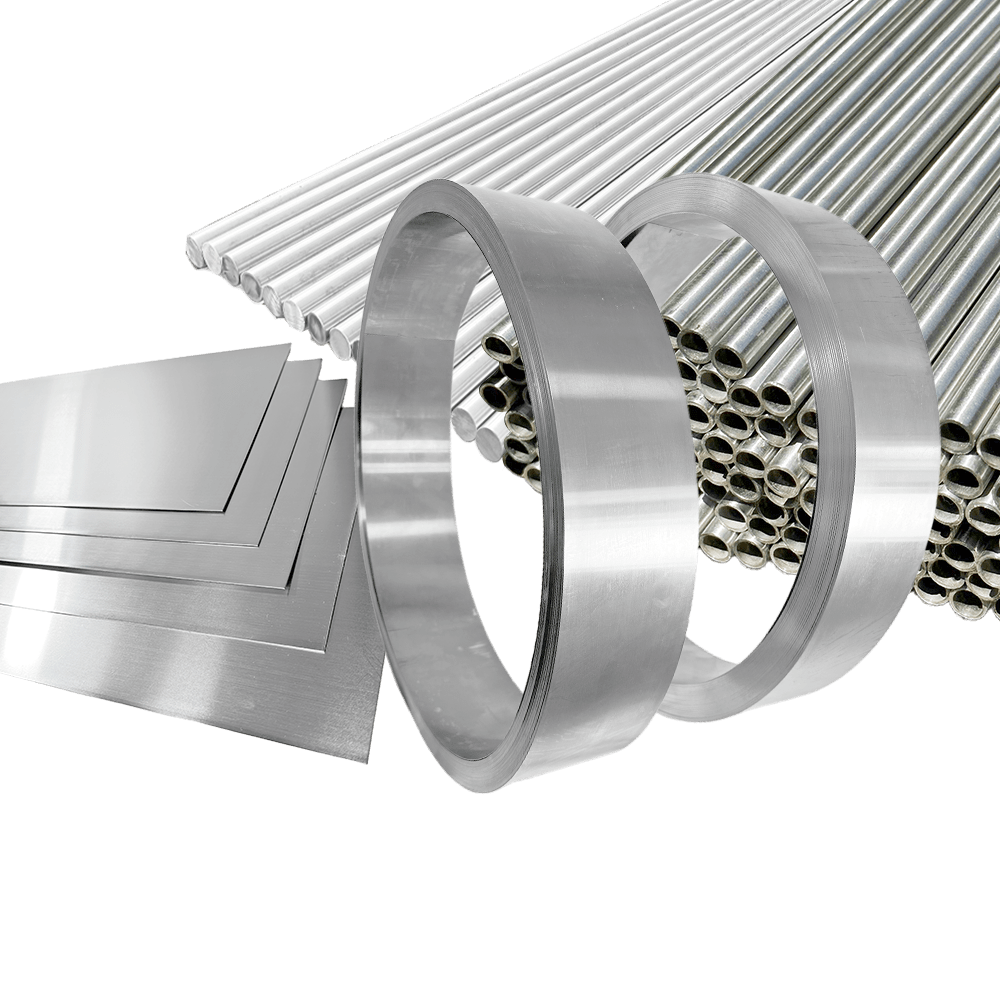

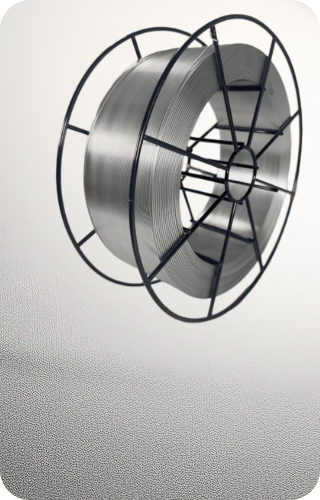

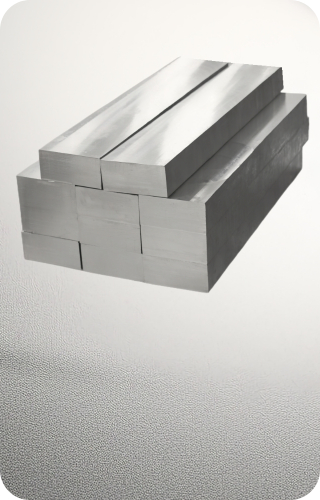

Substrate shape: axial wire/strip/straight strip

Alloy series: nickel-chromium iron alloy

Implementation standards: ASTM B564

Applications: aerospace, petrochemical, Marine, energy, industrial, automotive