Brand: KX-Alloy

Similar grades: GH4163 (China), Nimonic263, Alloy263, UNS NO7263, C263, NCK20D

Certification certificate: ISO9001:2015

Place of Origin: Danyang, Jiangsu, China

Alloy Category: High Temperature Alloy

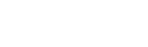

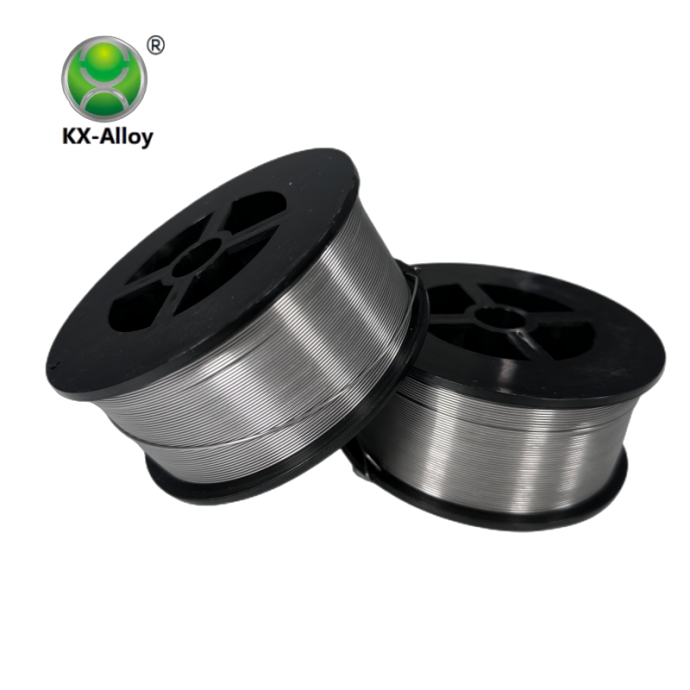

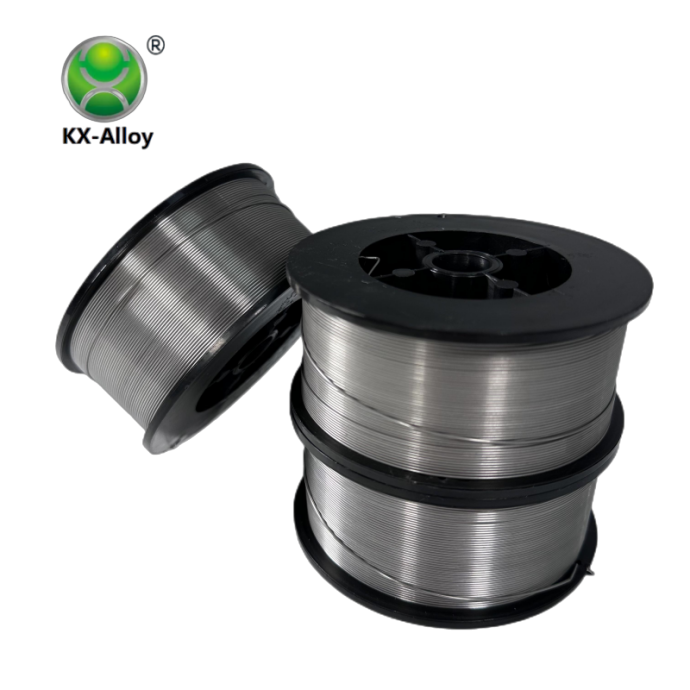

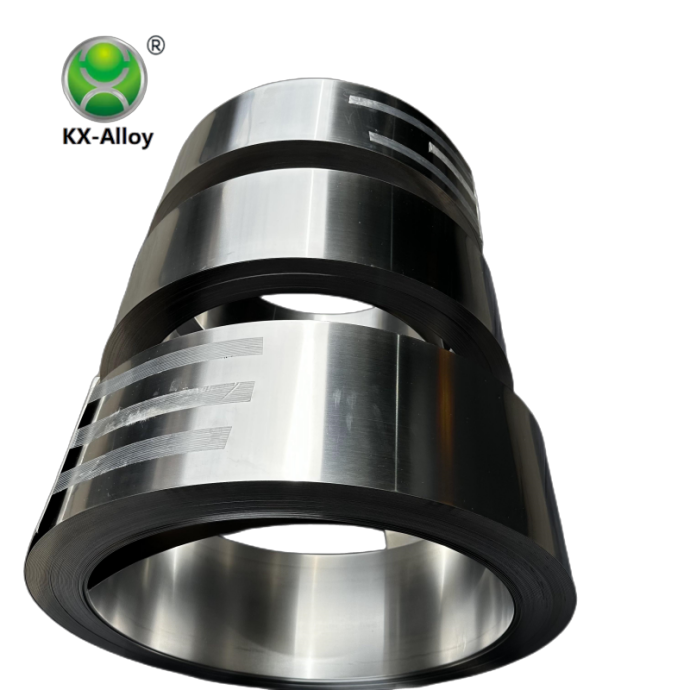

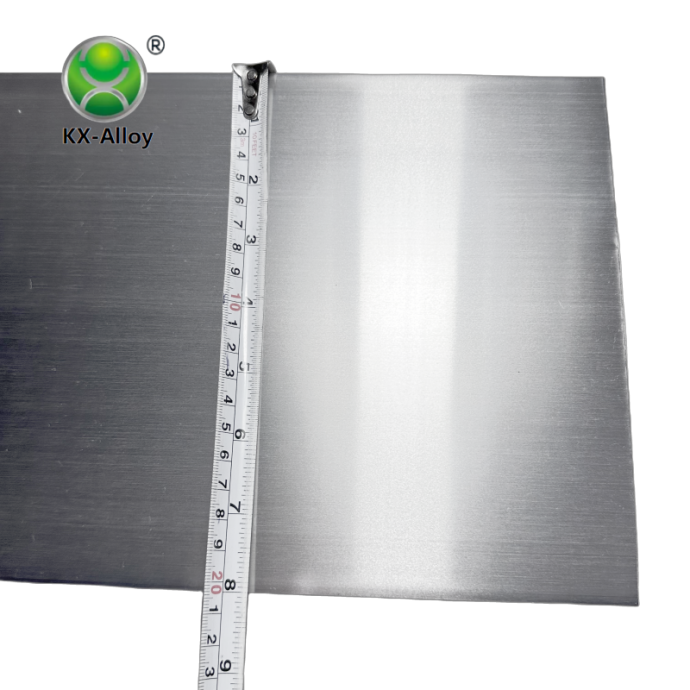

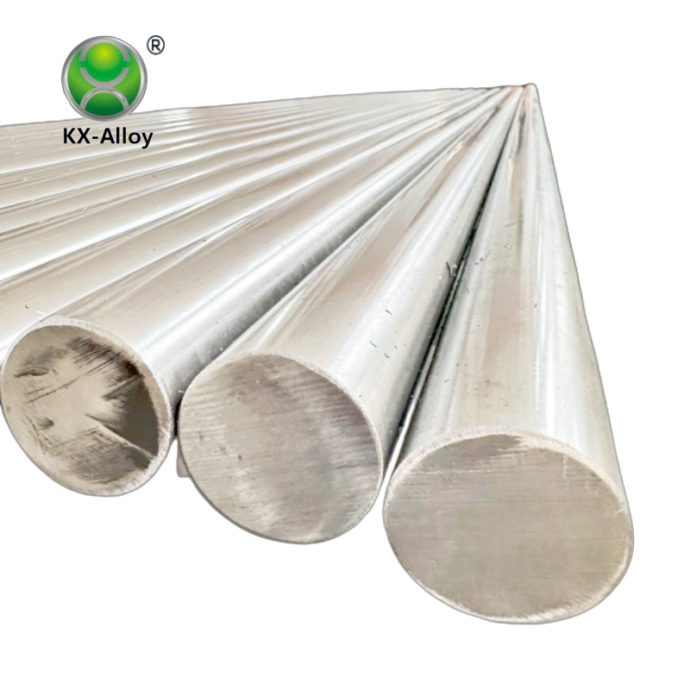

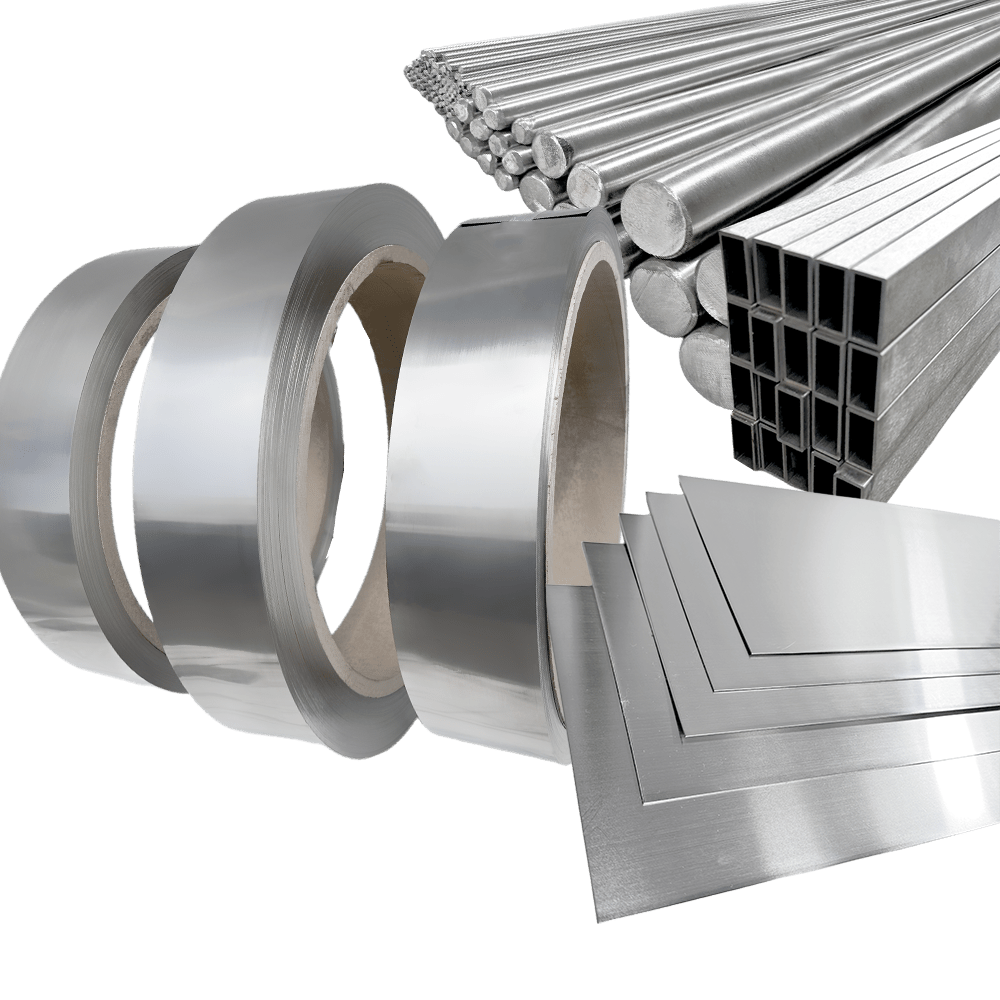

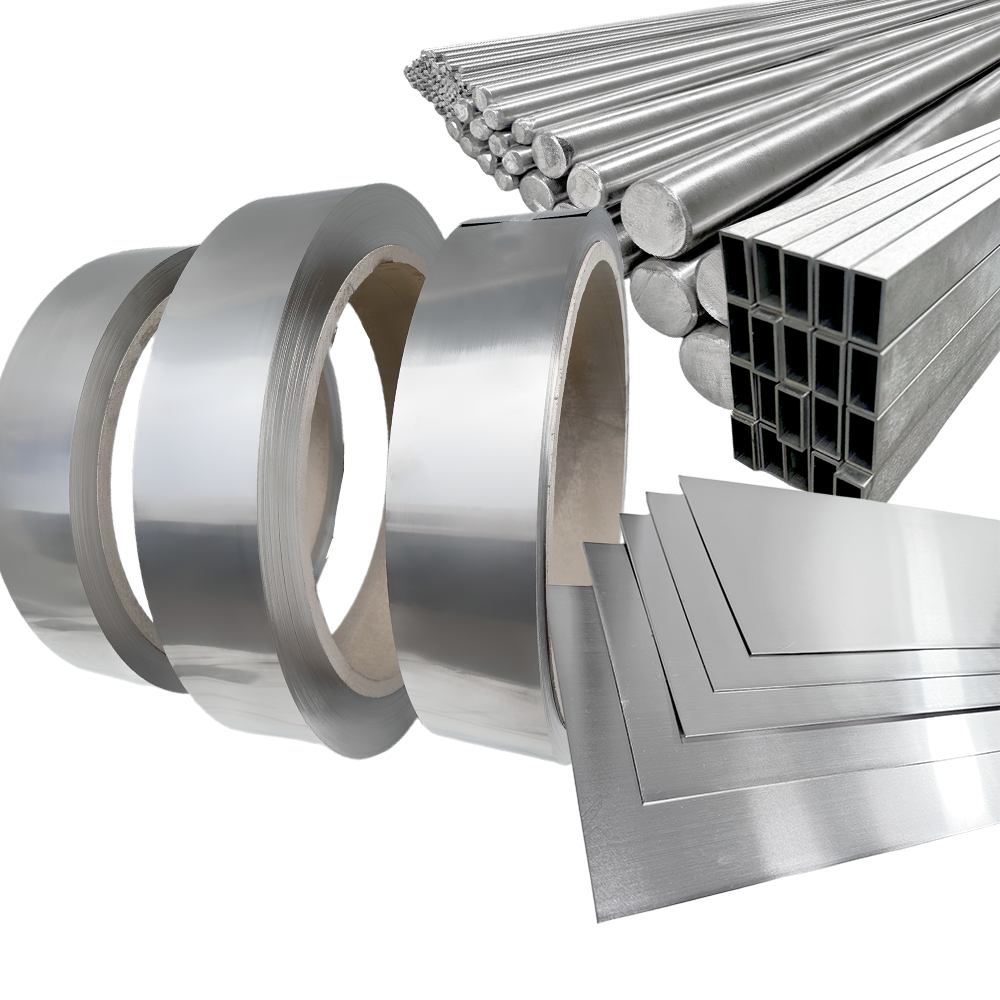

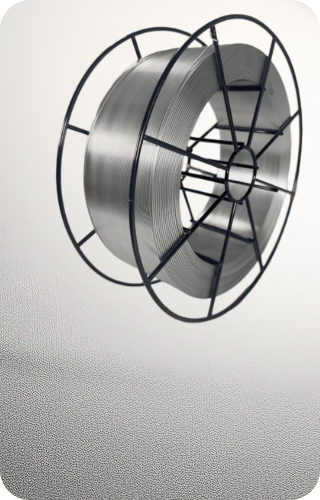

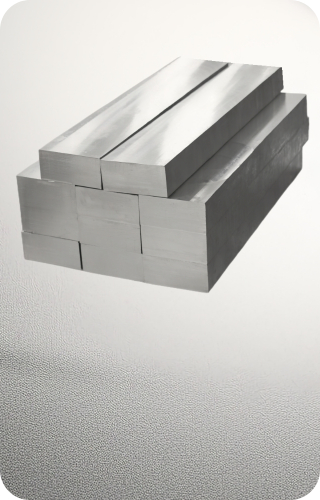

Substrate shape: wire/strip/rod/plate

Alloy Series: Nickel Chromium Cobalt Alloy

Implementation standards: ASTM, GB/T14992

Application areas: aerospace, machinery manufacturing