Brand: KX-Alloy

Similar grades:Hayness 188,UNSR30188,W.Nr.2.4683,KCN22W

Certification certificate: ISO9001:2015

Place of Origin: Danyang, Jiangsu, China

Alloy Category: High Temperature Alloy

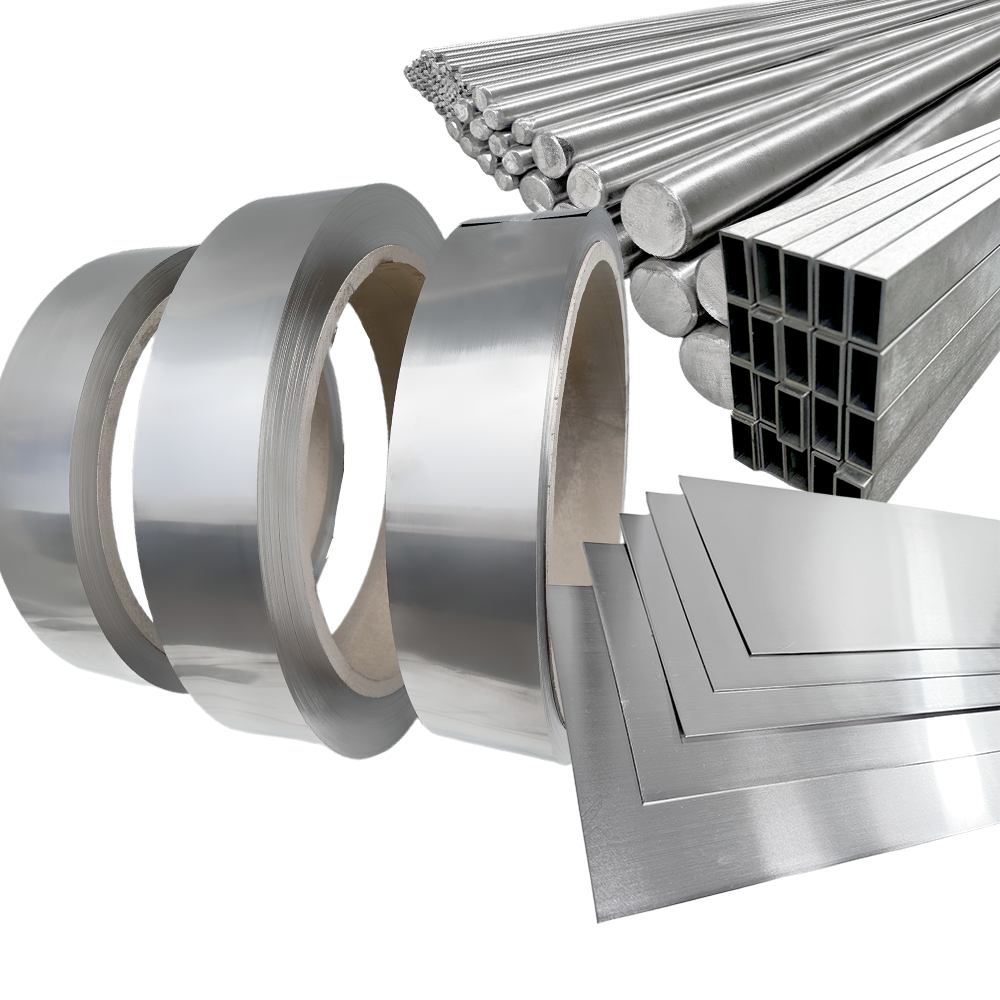

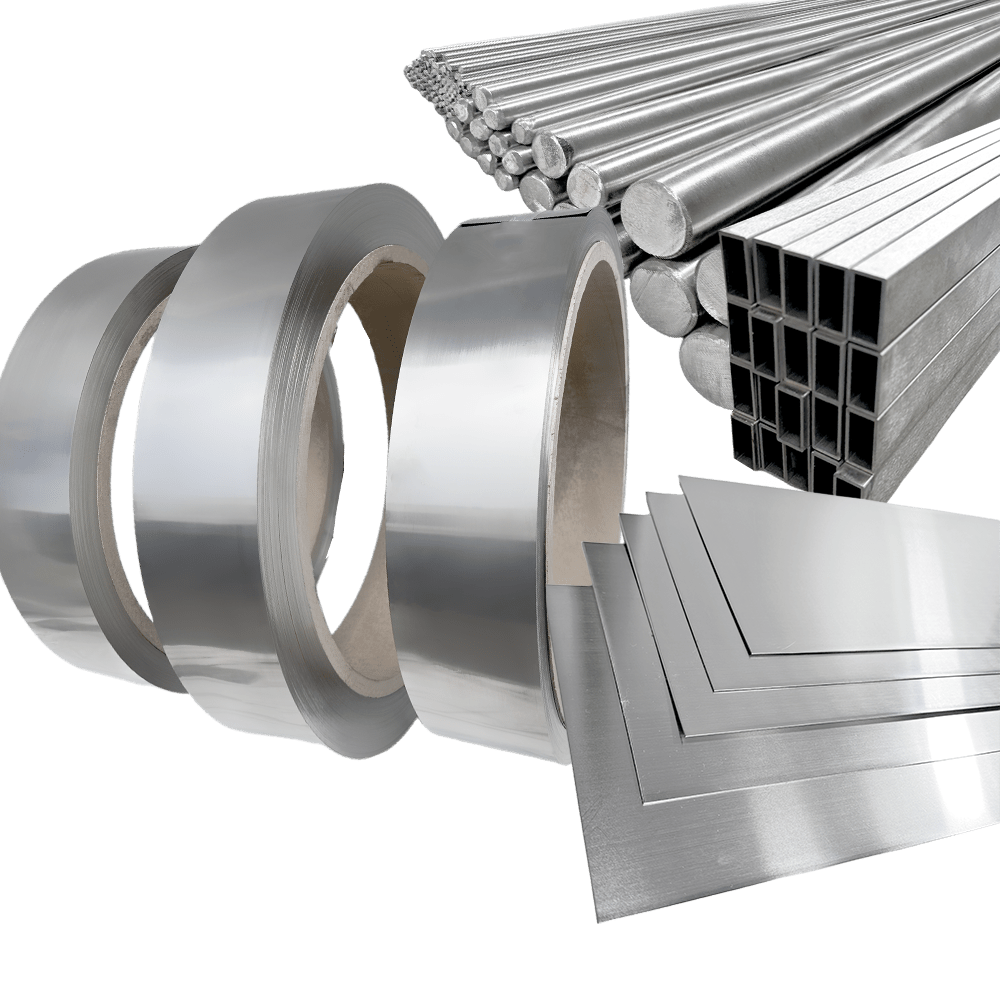

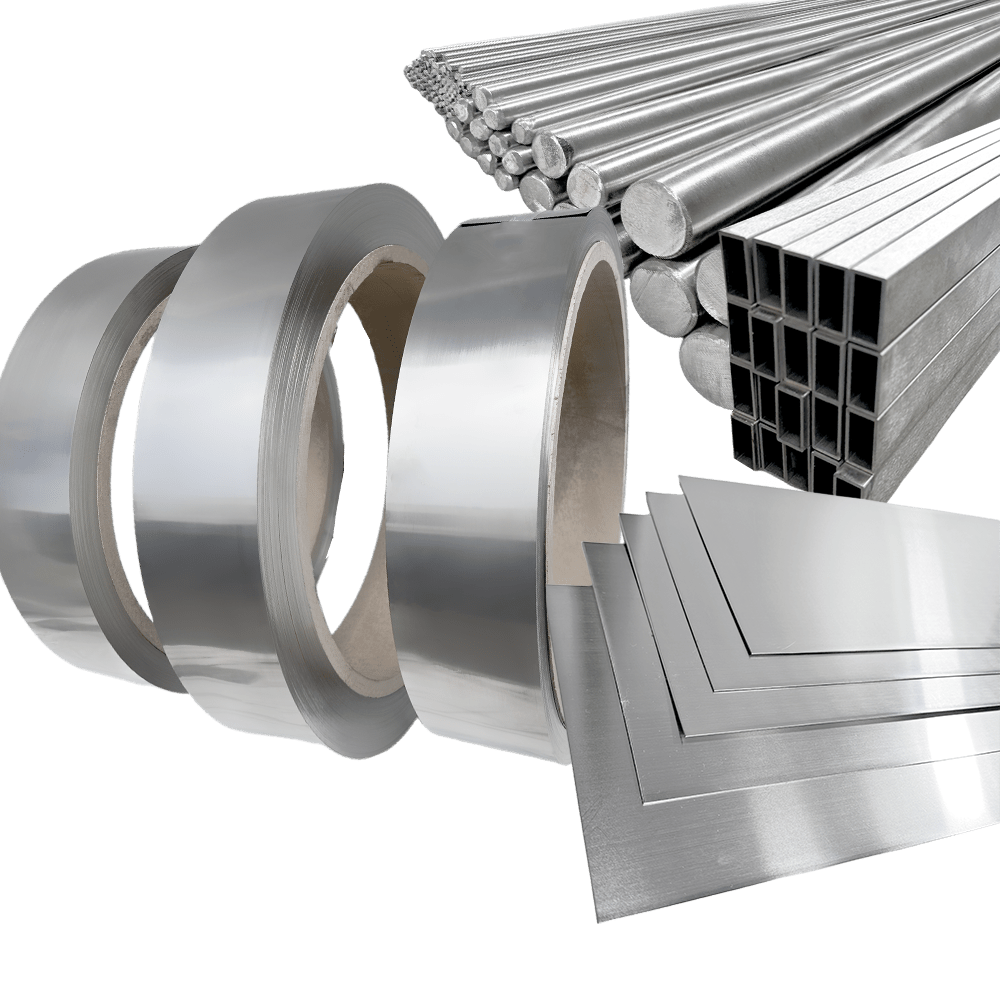

Substrate shape: wire/strip/rod/plate

Alloy Series: Nickel Chromium Cobalt Alloy

Implementation standards: ASTM, GB/T14992

Application areas:aerospace, automotive