Brand:KX-Alloy

Approximate brand:UNS N06625,Nr.2.4856,N06625,NC22DNb

Certification certificate:ISO9001:2015

Place of origin: Danyang, Jiangsu, China

Alloy category: corrosion resistant alloy

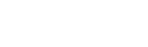

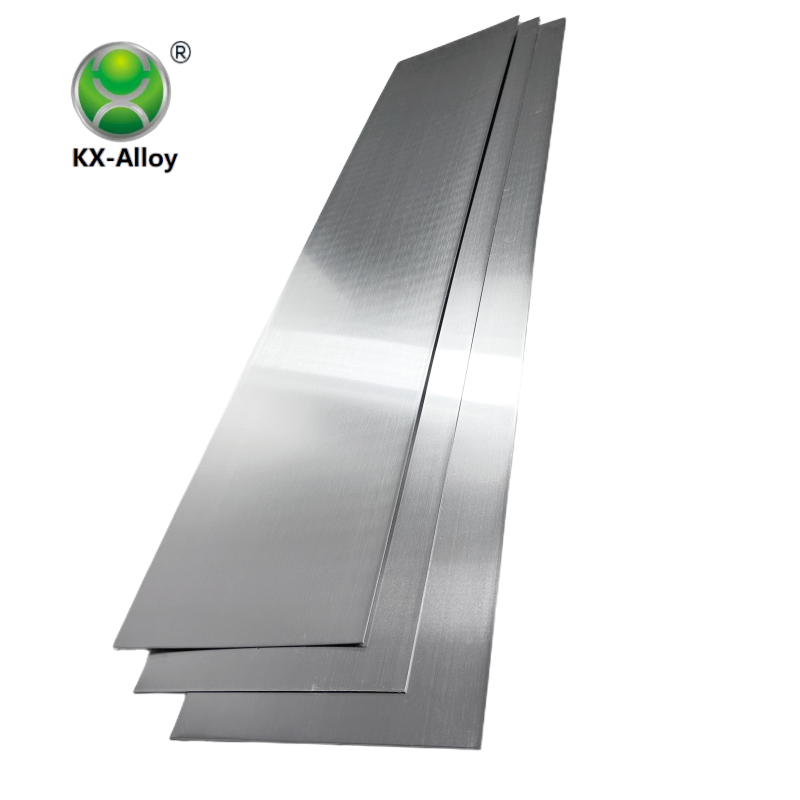

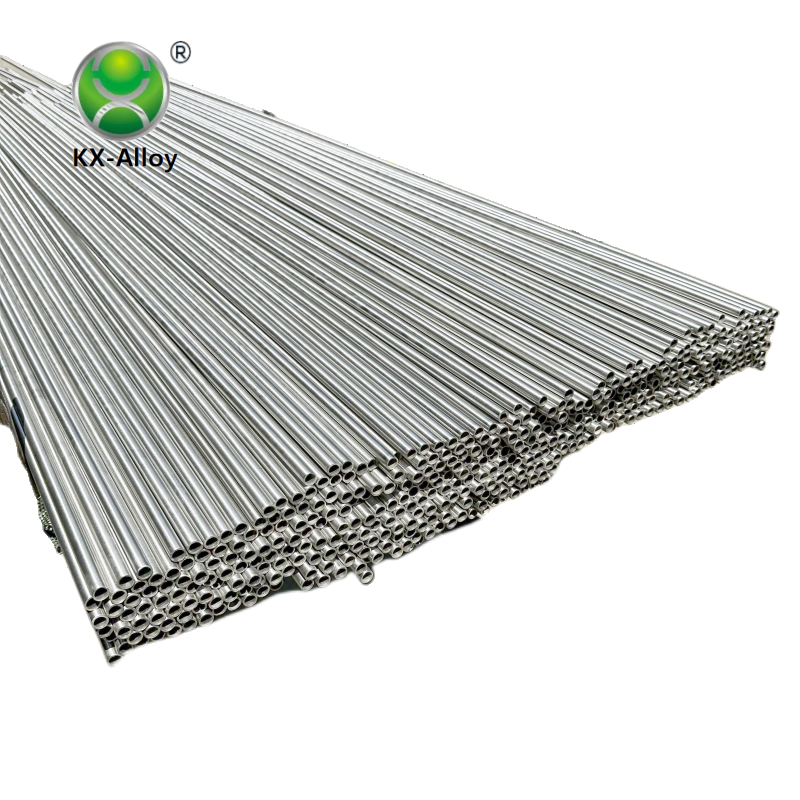

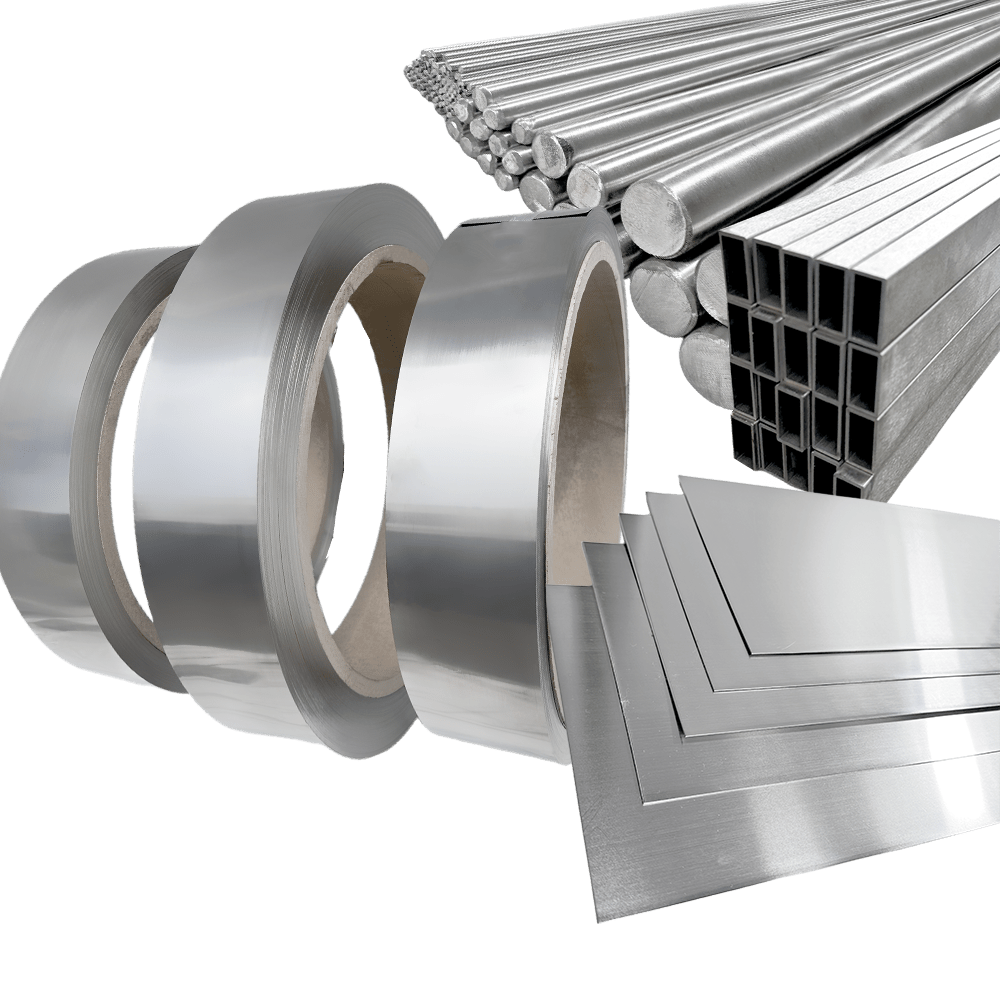

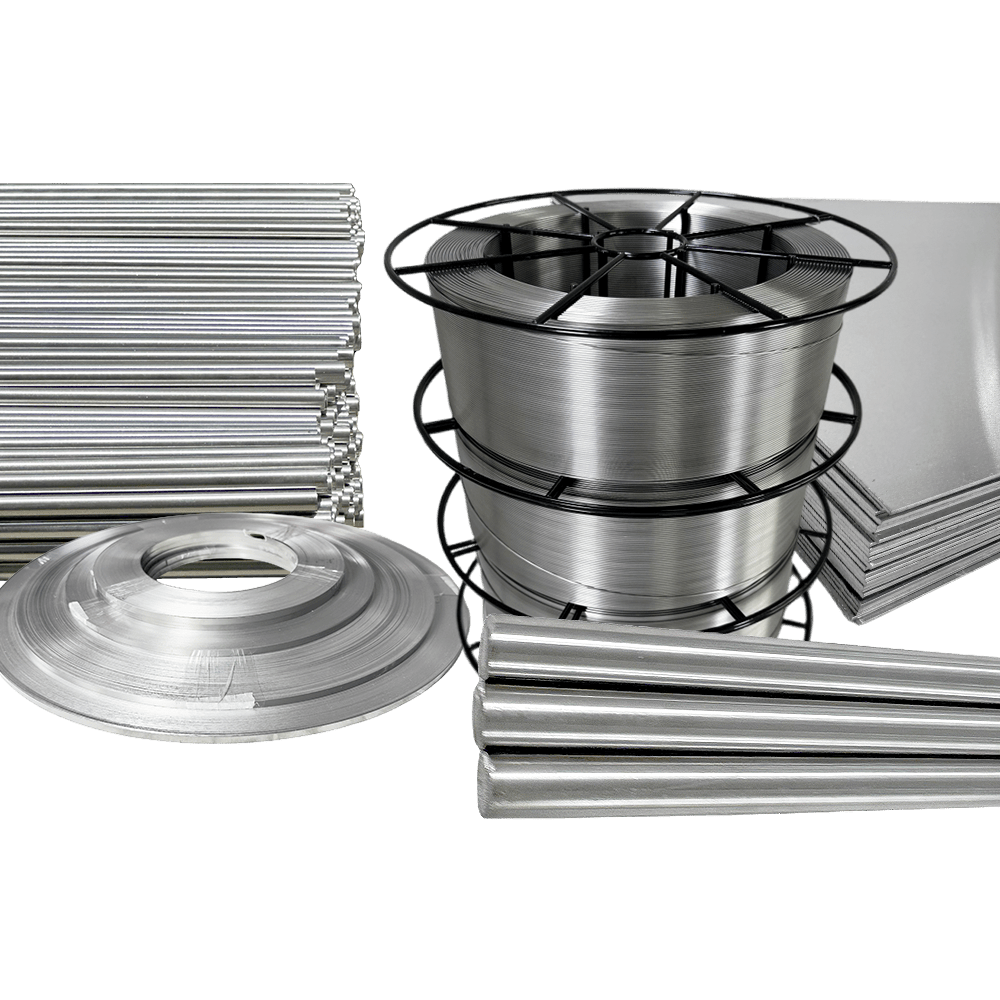

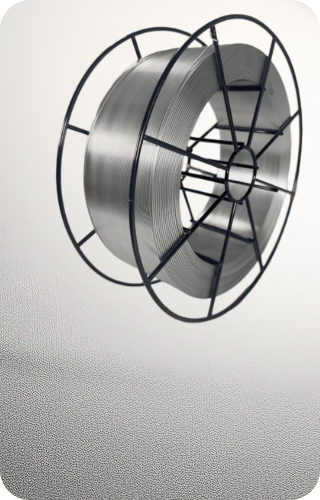

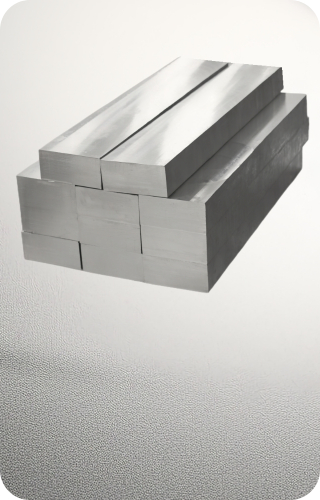

Substrate shape: axial wire/strip/straight strip

Alloy series: nickel chromium molybdenum alloy

Executive standard:ASTM B564

Applications: aerospace, Marine, petrochemical, energy, industrial fields