Brand: KX-Alloy

Approximate grade: UNS N06601 W.Nr 2.4851

Certification certificate: ISO9001:2015

Place of Origin: Danyang, Jiangsu, China

Alloy Category: Corrosion Resistant Alloy

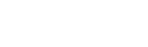

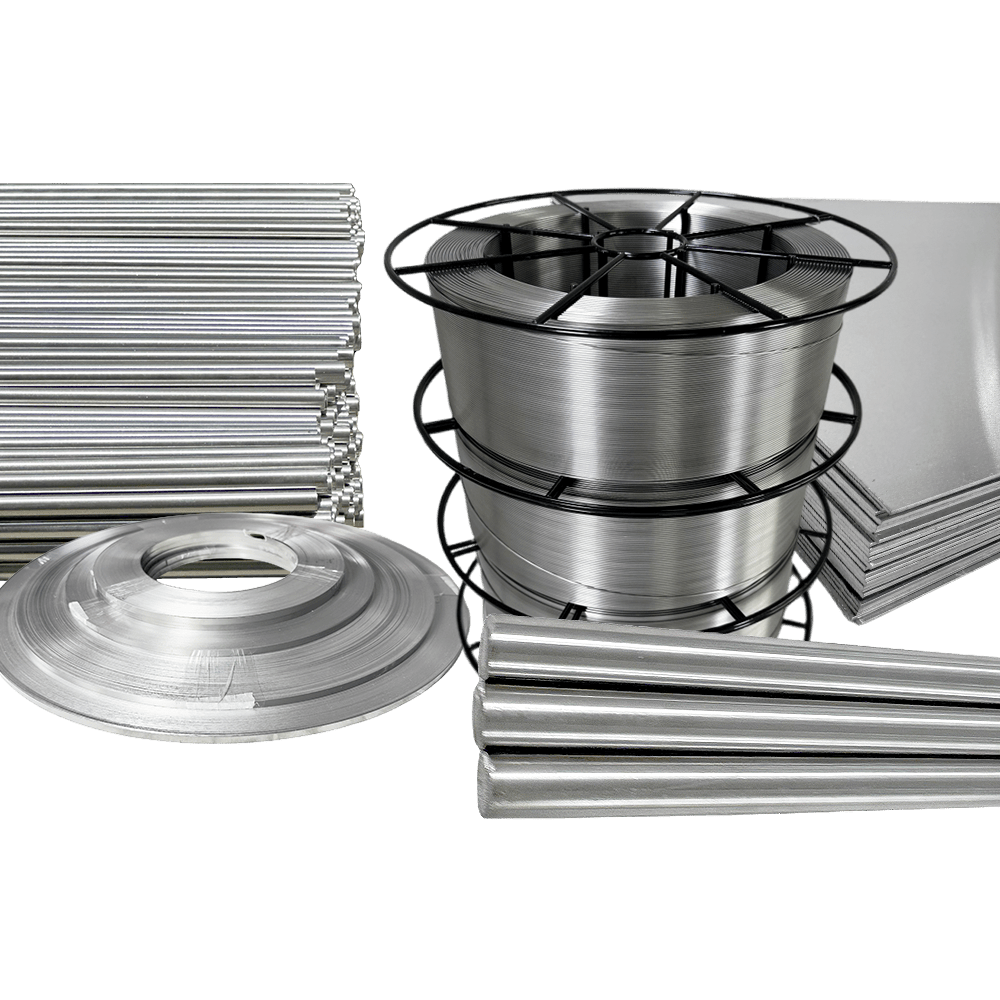

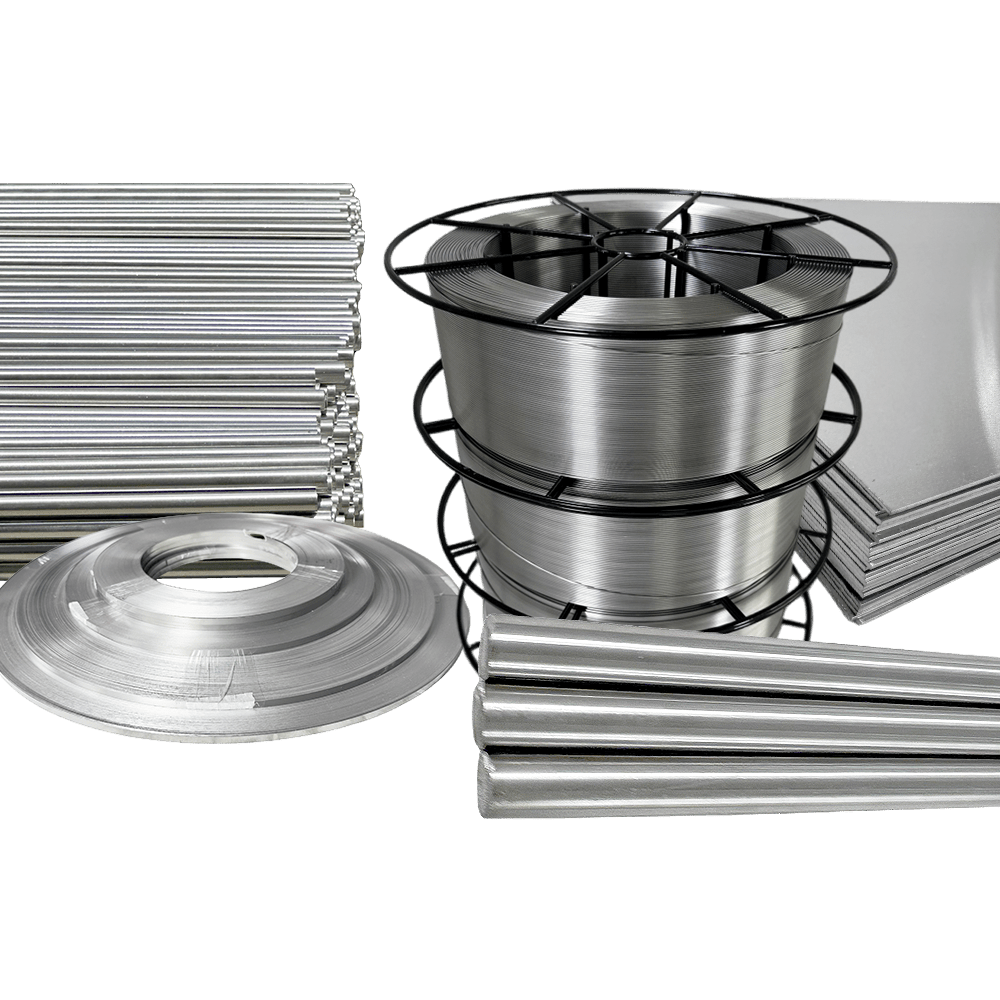

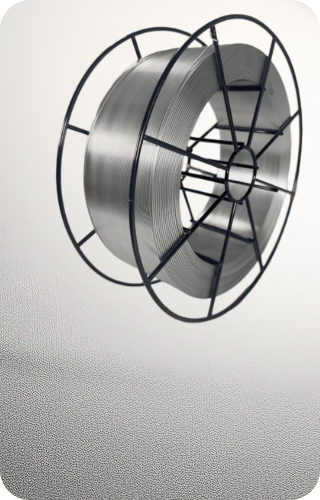

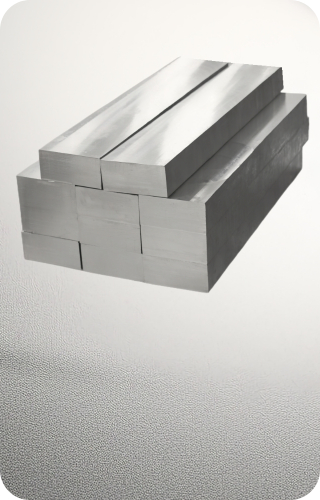

Substrate shape: axis filament/strip/straight strip

Alloy series: nickel-chromium-iron alloy

Implementation standards: ASTM

Application fields: automotive, petrochemical, industrial, aerospace, energy