Brand: KX-Alloy

Approximate grades: UNS NO4400, NCu30, Alloy400, NW4400, W.Nr.2.4360

Certification certificate: ISO9001:2015

Place of Origin: Danyang, Jiangsu, China

Alloy Category: Monel Alloy

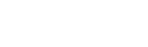

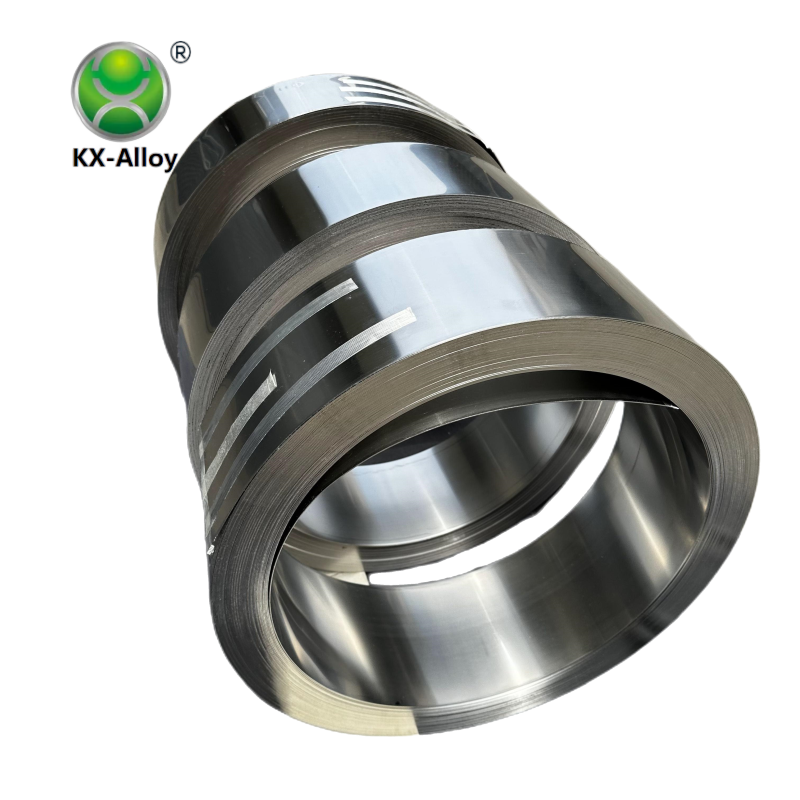

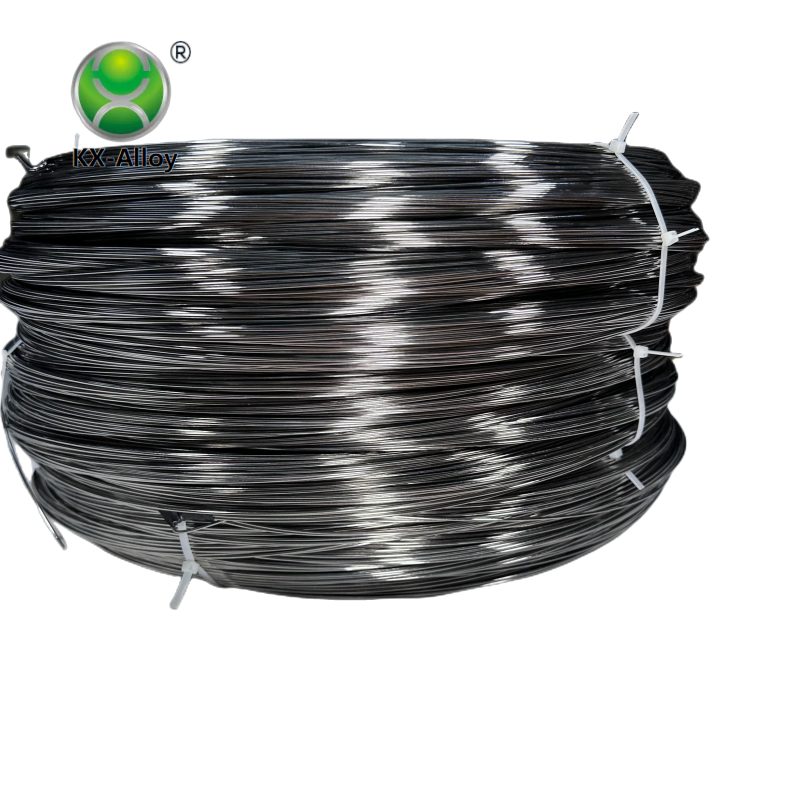

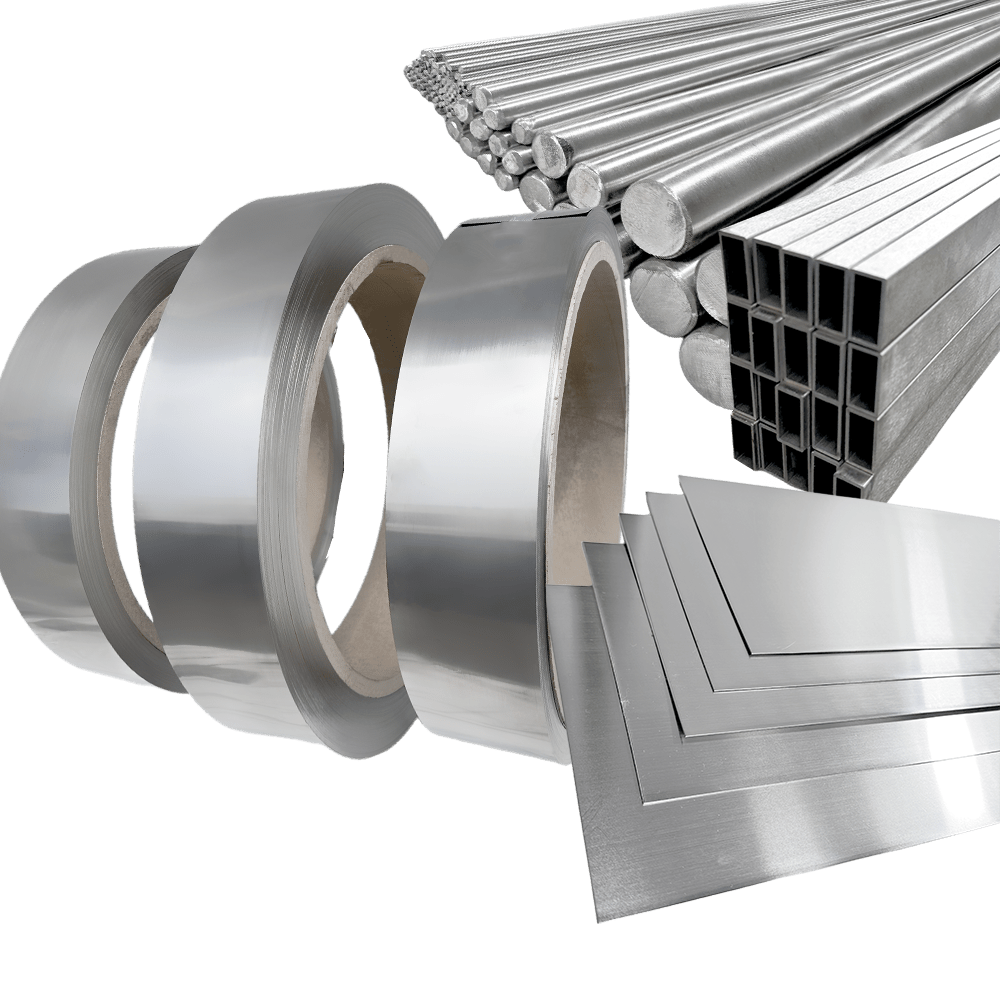

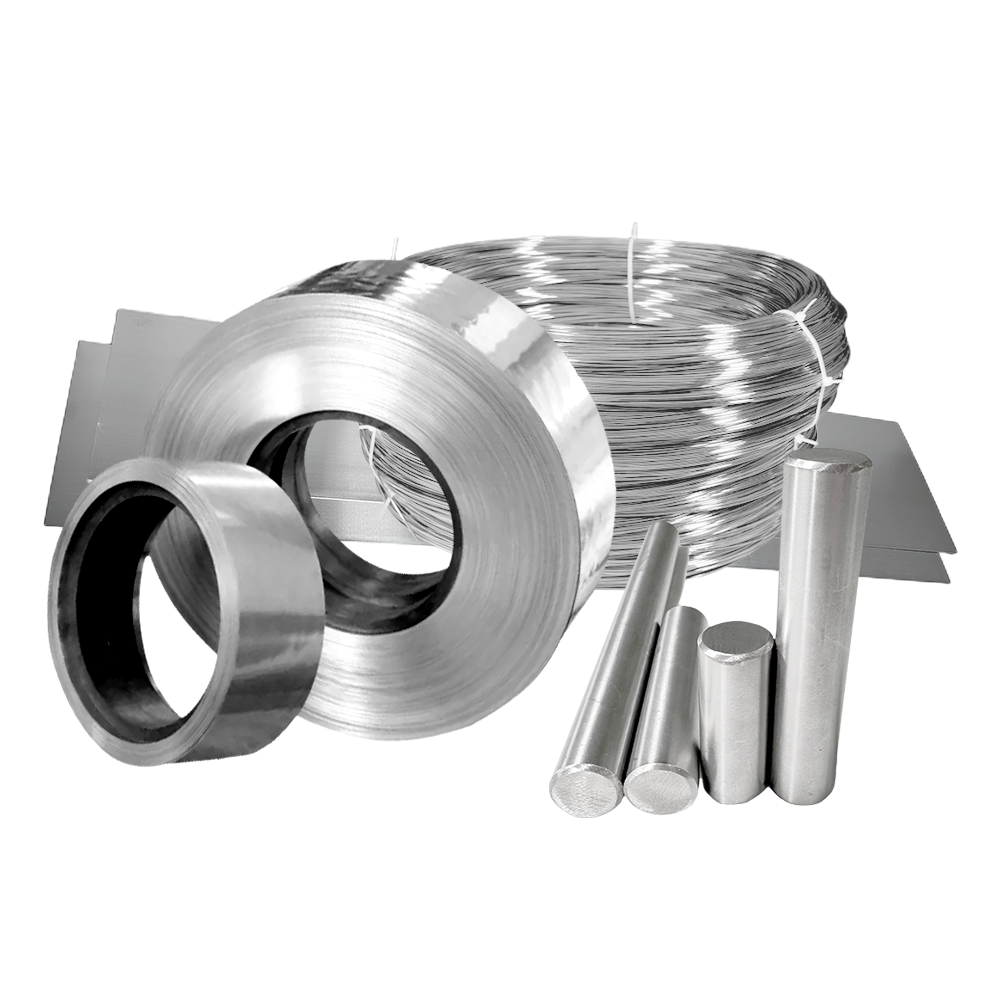

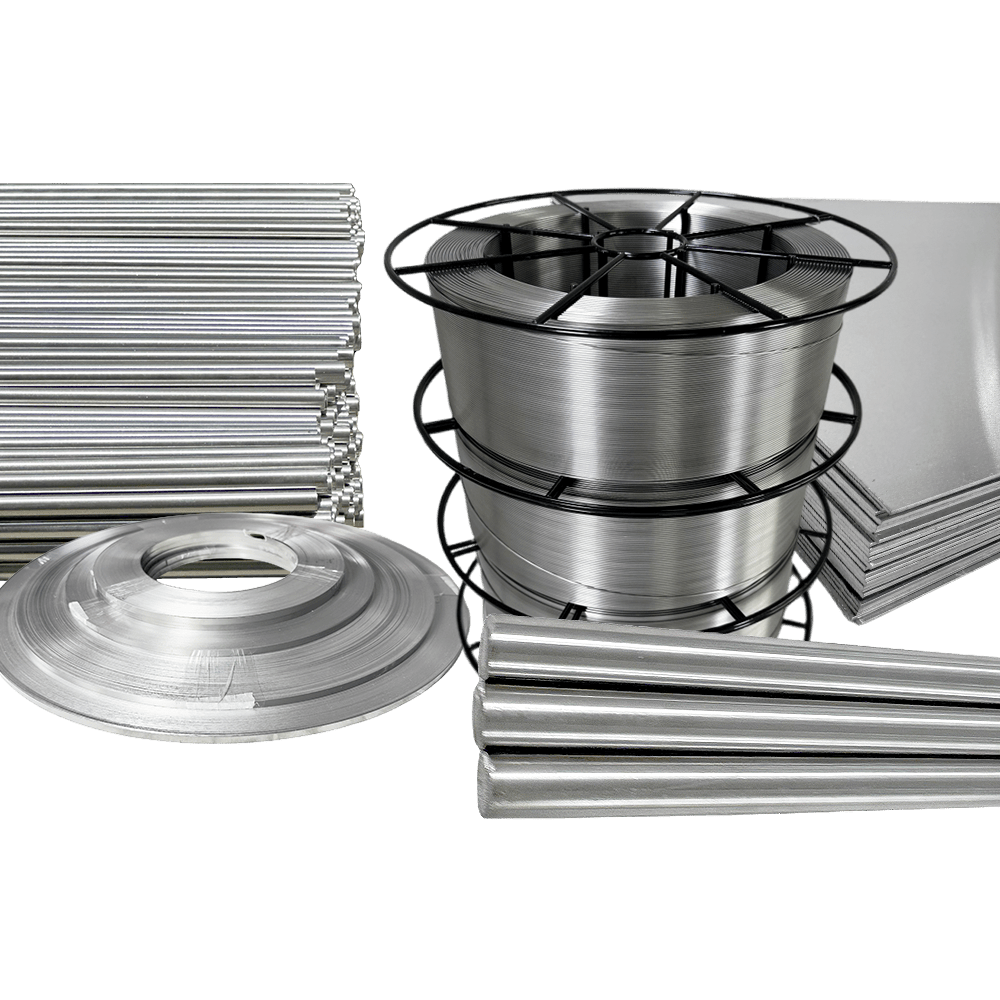

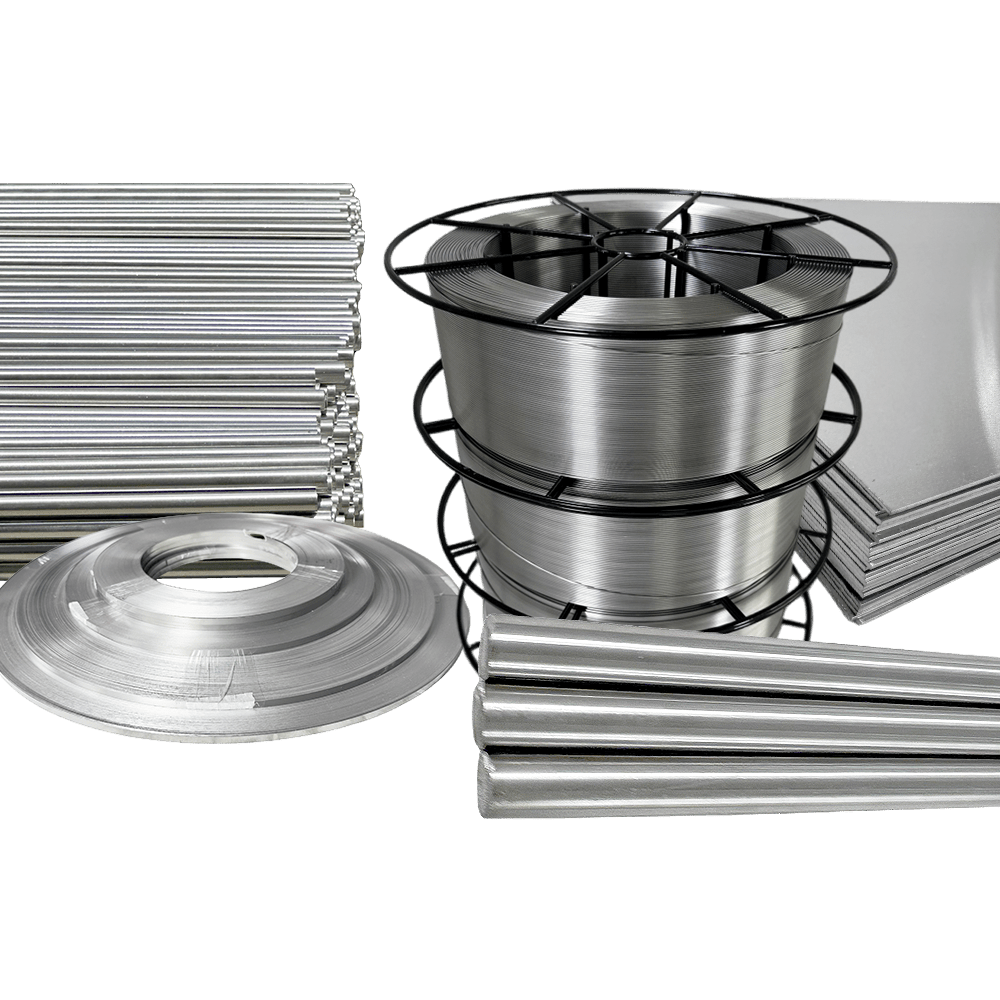

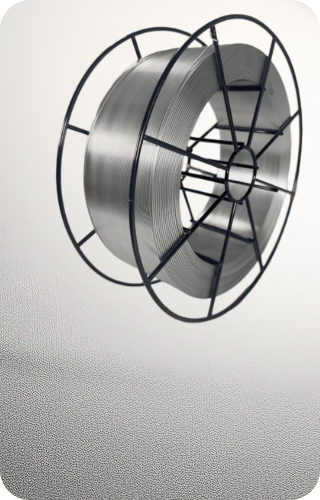

Substrate shape: coiled wire/strip/straight strip

Alloy Series: Nickel Copper Alloy

Implementation standard: ASTM B164

Application fields: automobile field, marine ship, petrochemical industry, industrial field