Brand: KX-Alloy

Similar grades: UNS N08825、NCF825

Certification certificate: ISO9001:2015

Place of Origin: Danyang, Jiangsu, China

Alloy Category: Corrosion Resistant Alloy

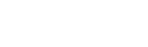

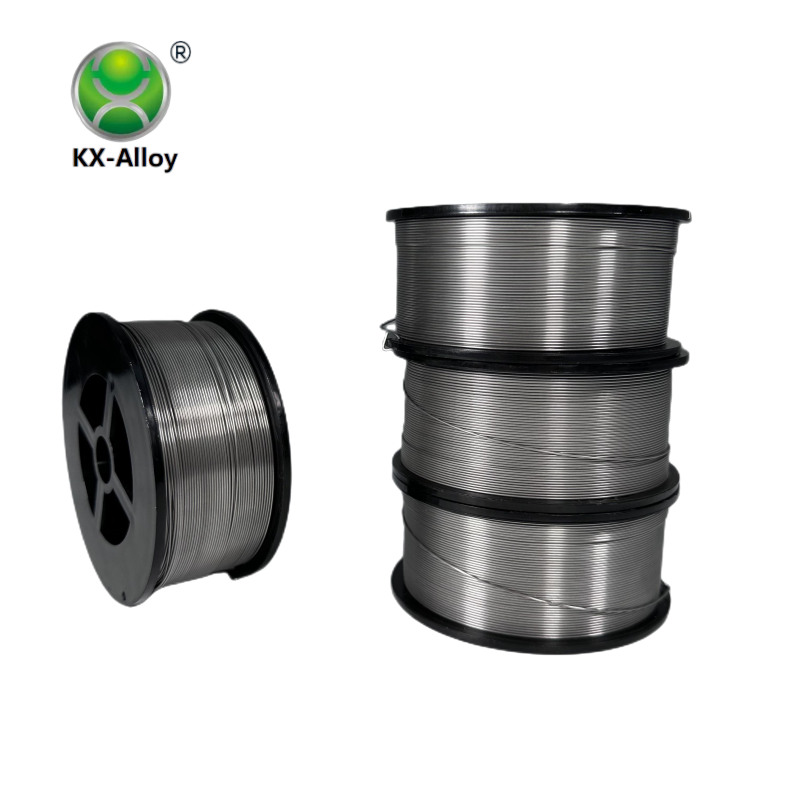

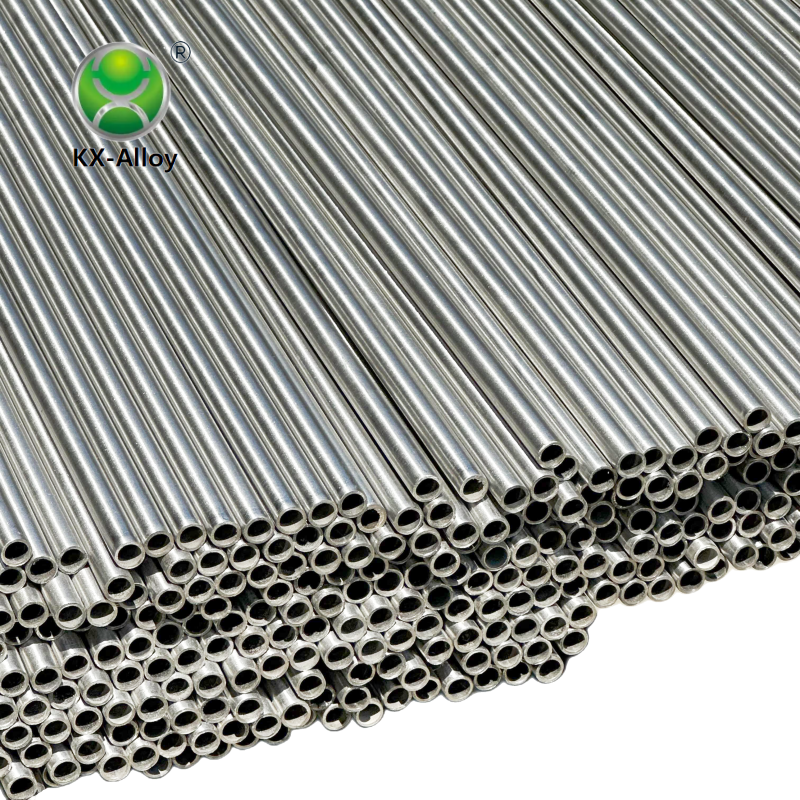

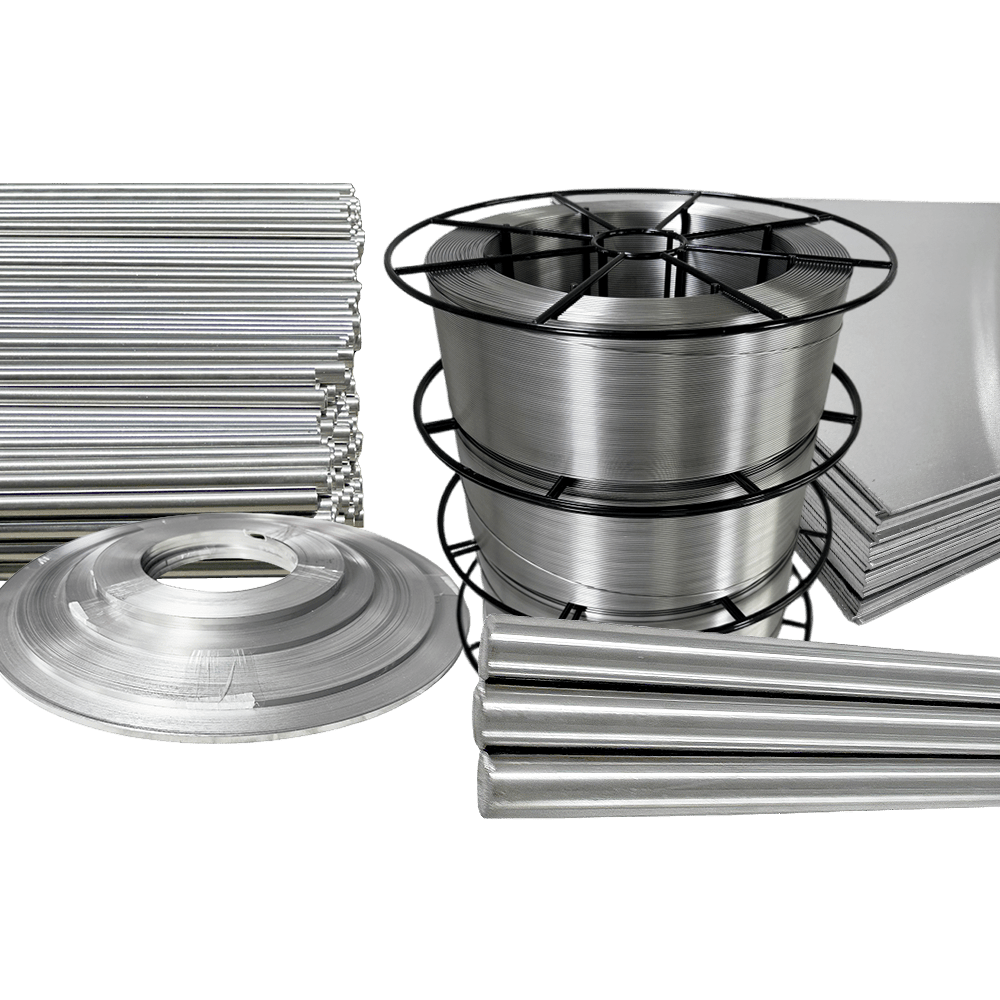

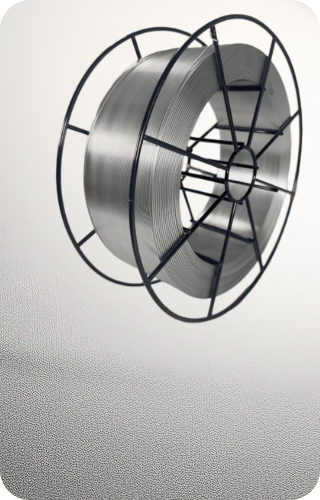

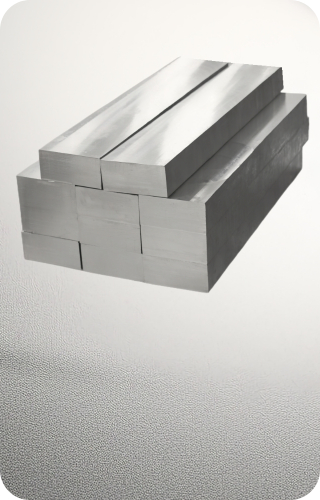

Substrate shape: shaft wire/strip/straight strip

Alloy series: nickel-chromium iron alloy

Implementation standards: ASTM B564

Applications: marine ships, petrochemical, energy field