Brand: KX-Alloy

Similar grades: GH4033,ЭП437БГ,ХН77ТЮР

Certification certificate: ISO9001:2015

Place of Origin: Danyang, Jiangsu, China

Alloy Category: High Temperature Alloy

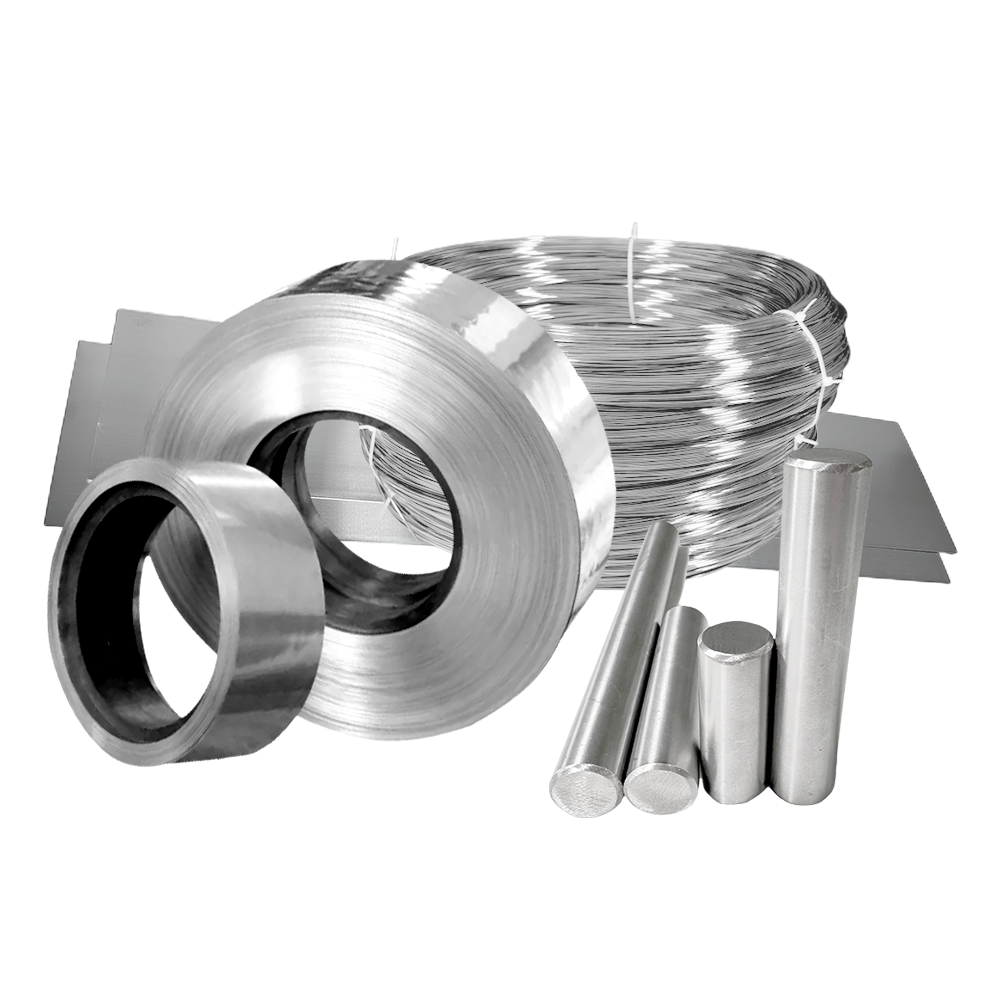

Substrate shape:wire/strip/bar/pipe/plate

Alloy series: nickel-chromium alloy

Implementation standards:ASTM

Application areas:aerospace, petrochemicals, energy