Brand: KX-Alloy

Approximate grades: UNS R30188, GH5188, Haynes188, W.Nr.2.4683

Certification certificate: ISO9001:2015

Place of Origin: Danyang, Jiangsu, China

Alloy Category: Hastelloy

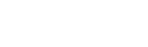

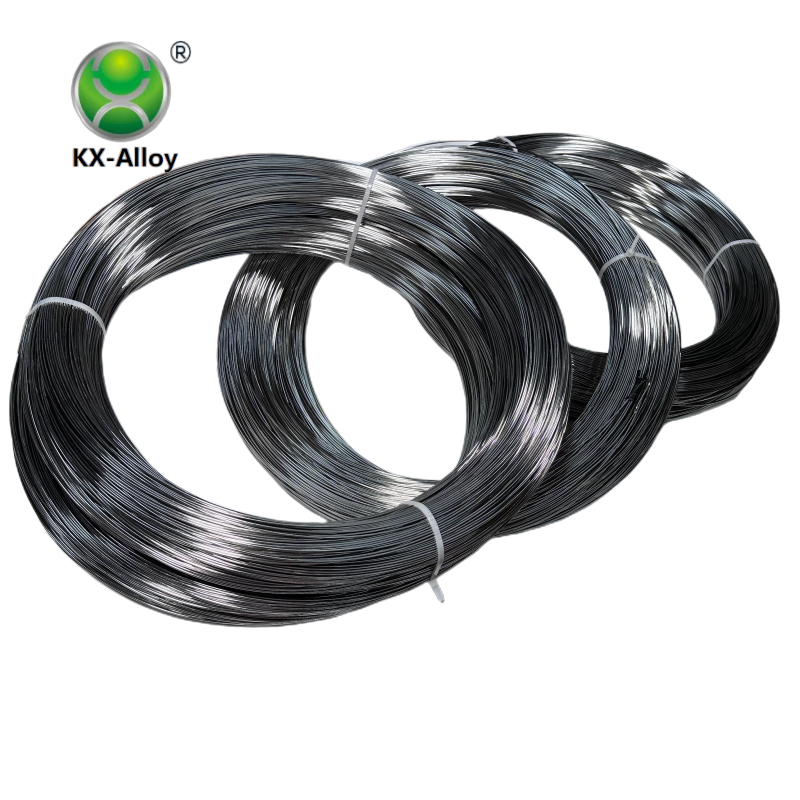

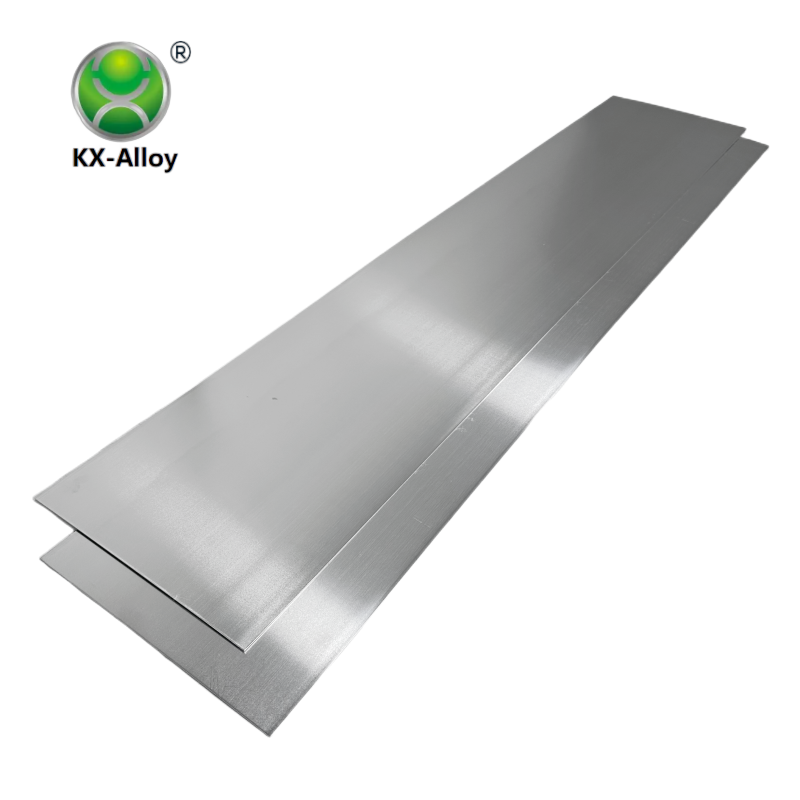

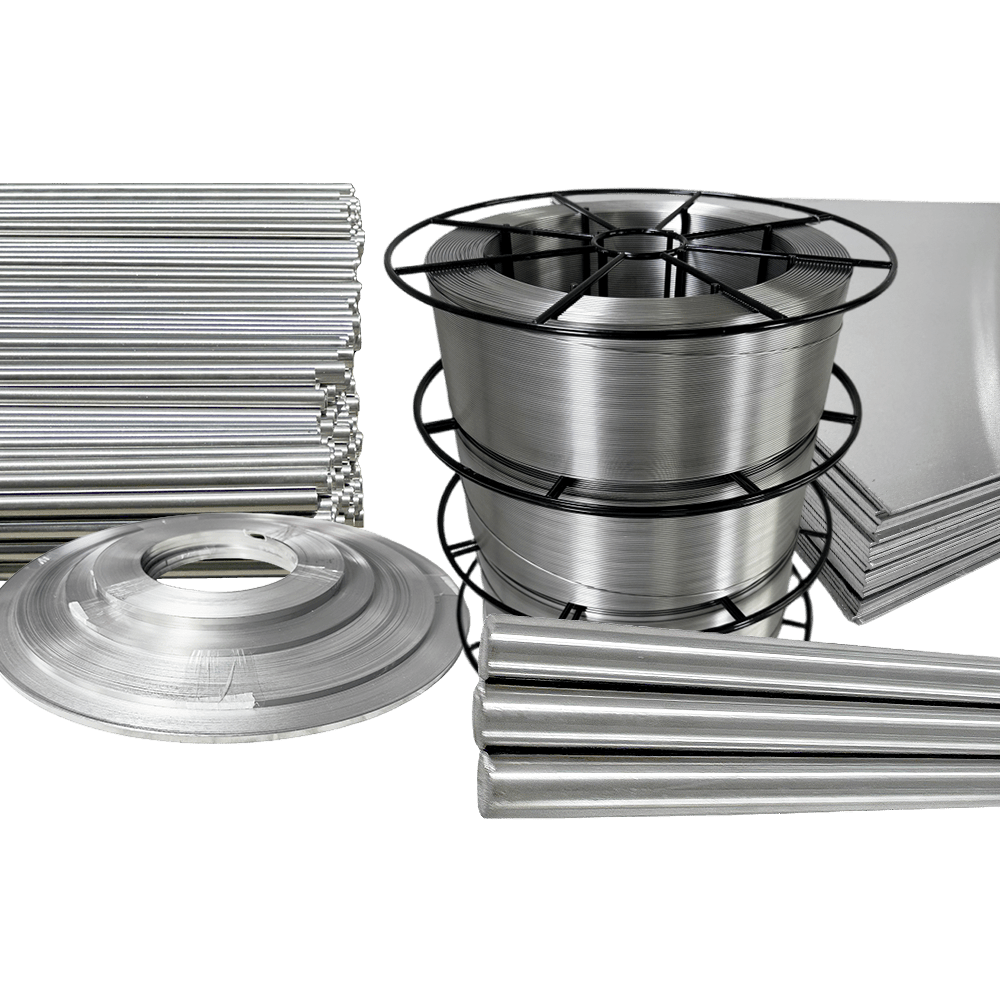

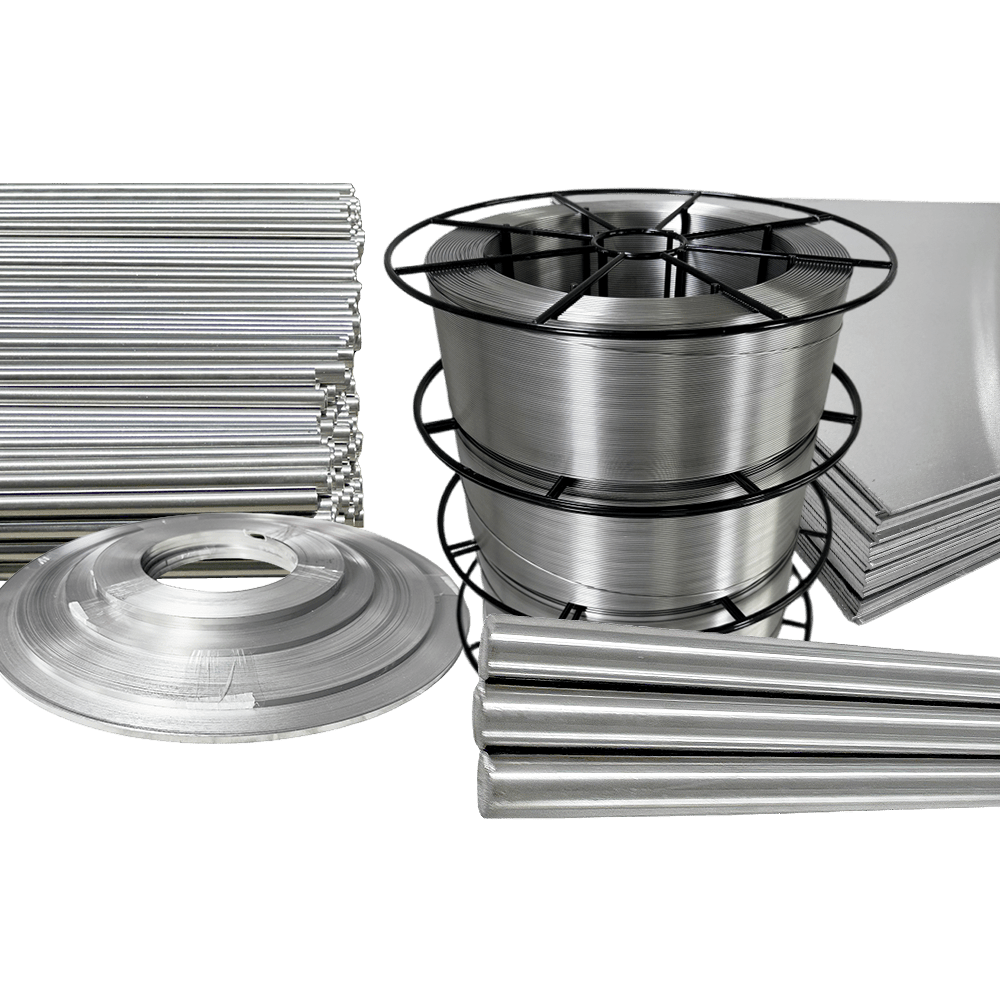

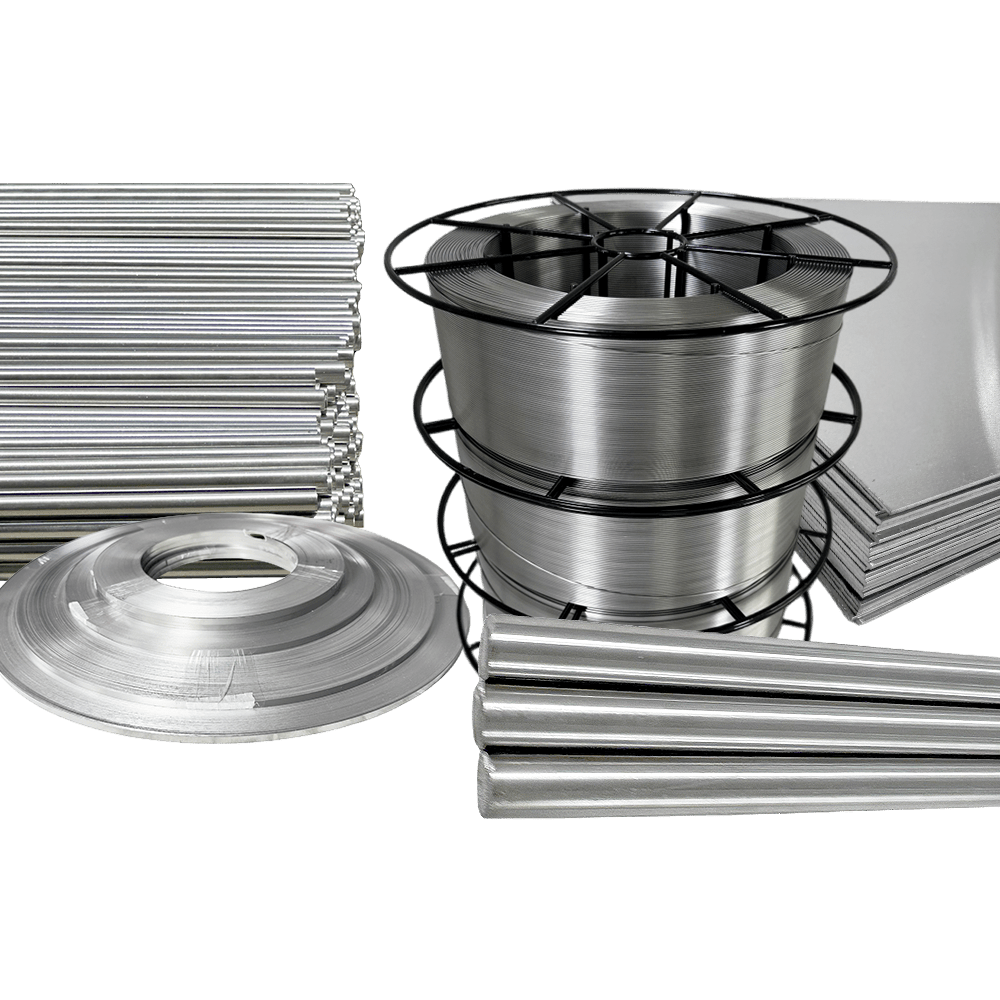

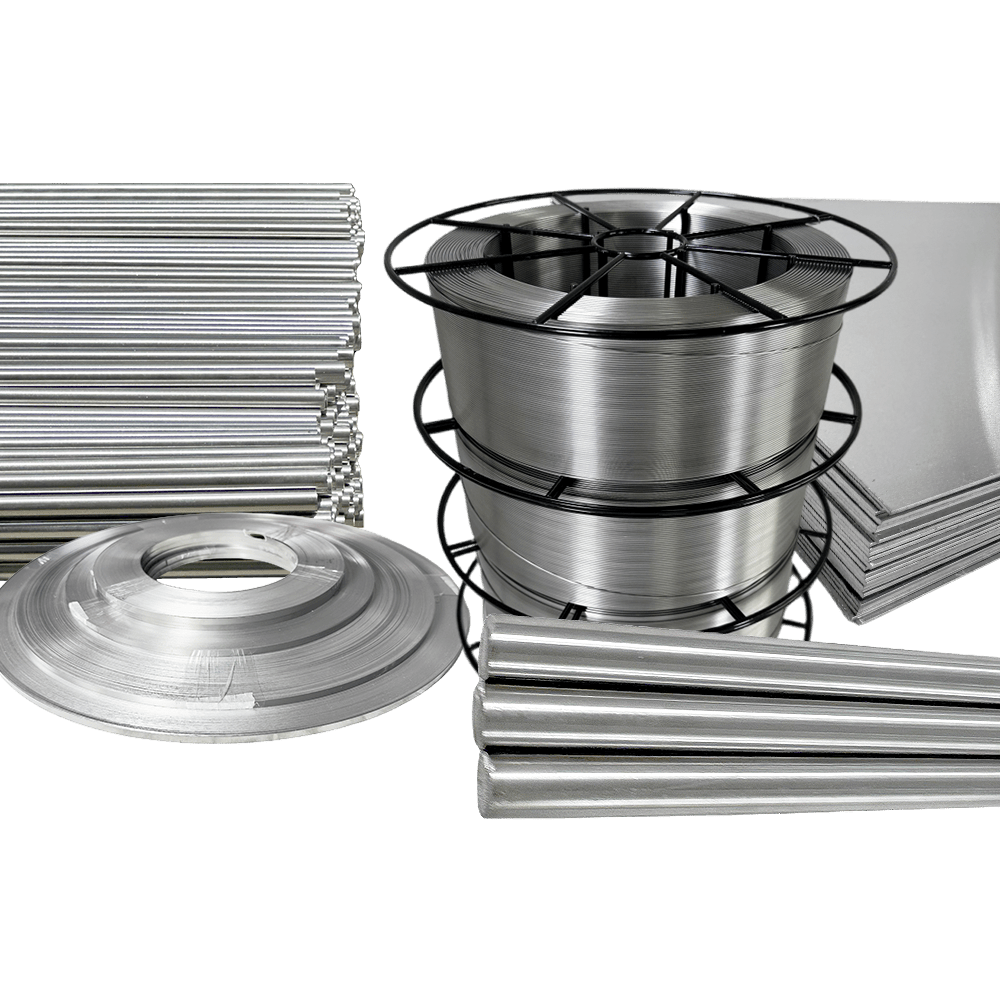

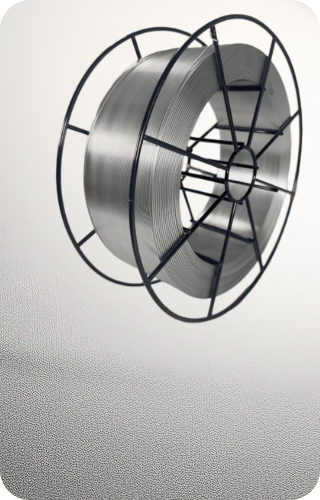

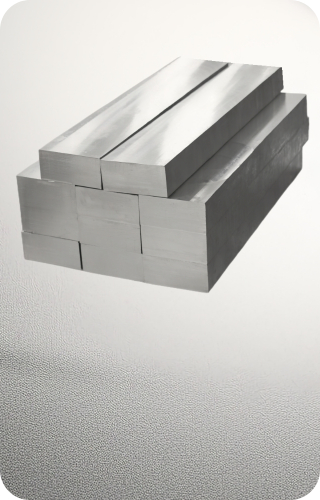

Substrate shape: wire/strip/rod/pipe/plate

Alloy Series: Nickel Chromium Cobalt Alloy

Implementation standard: GB /T 14992

Application areas: aerospace, industrial fields