Brand: KX-Alloy

Similar grades:40XHIO, 0Cr40Ni55Al3,3J40

Certification certificate:ISO9001:2015

Place of Origin: Danyang, Jiangsu, China

Alloy Category: Elastic Alloy

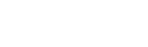

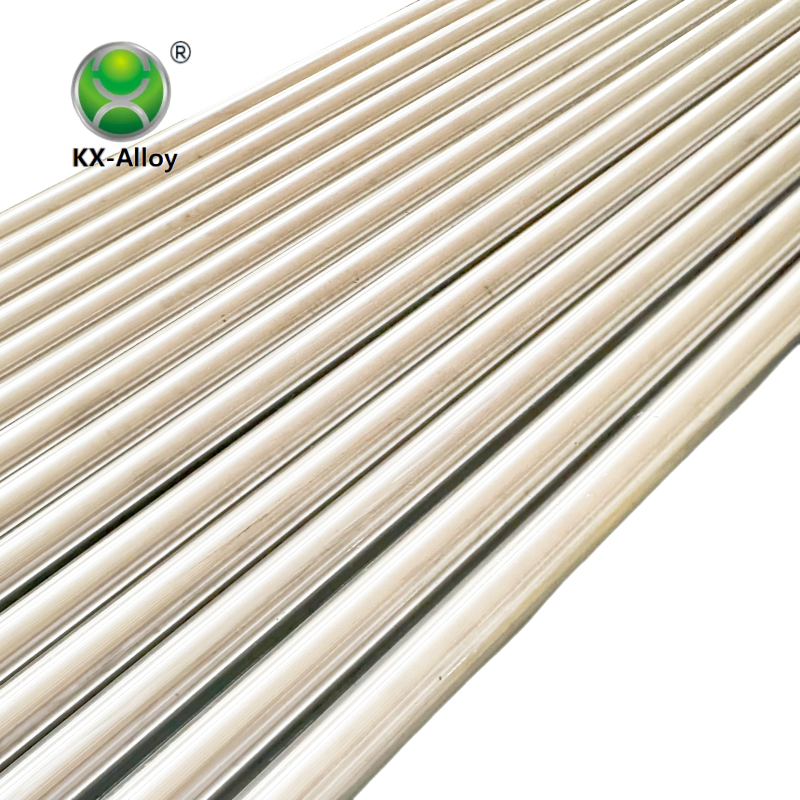

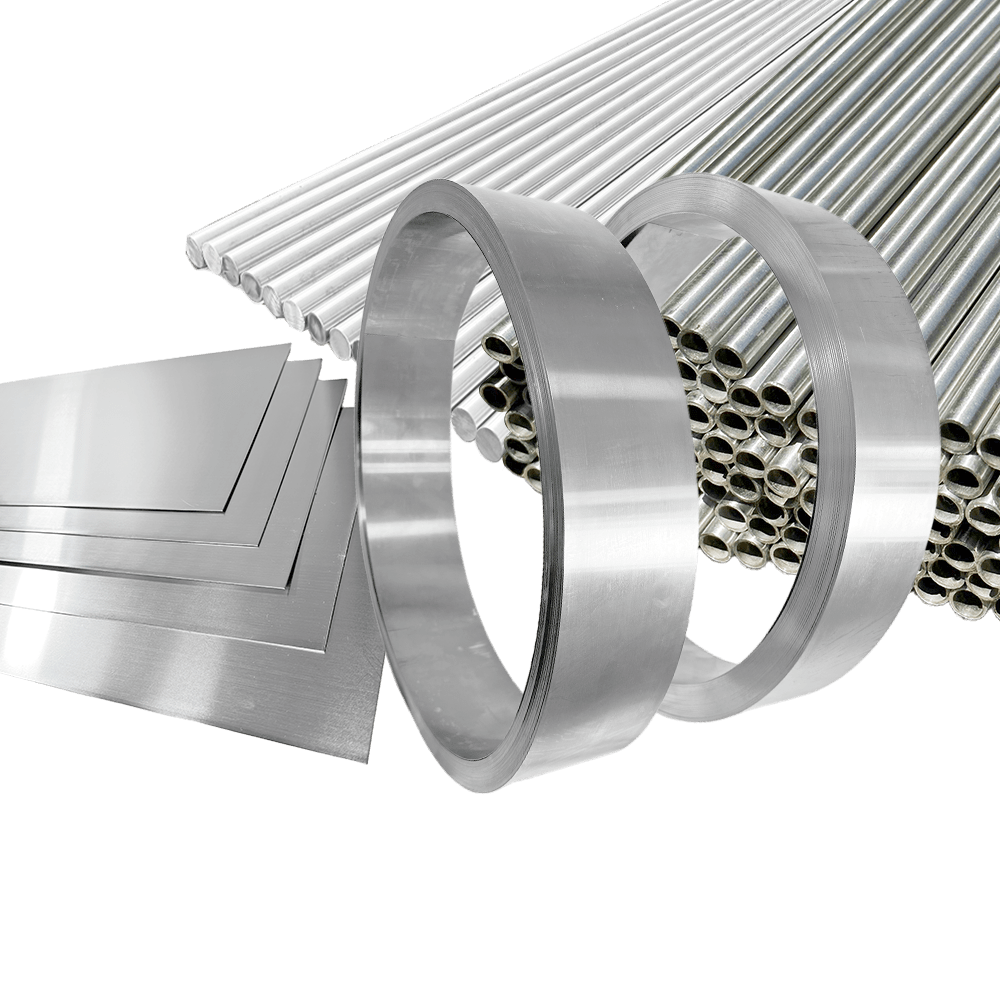

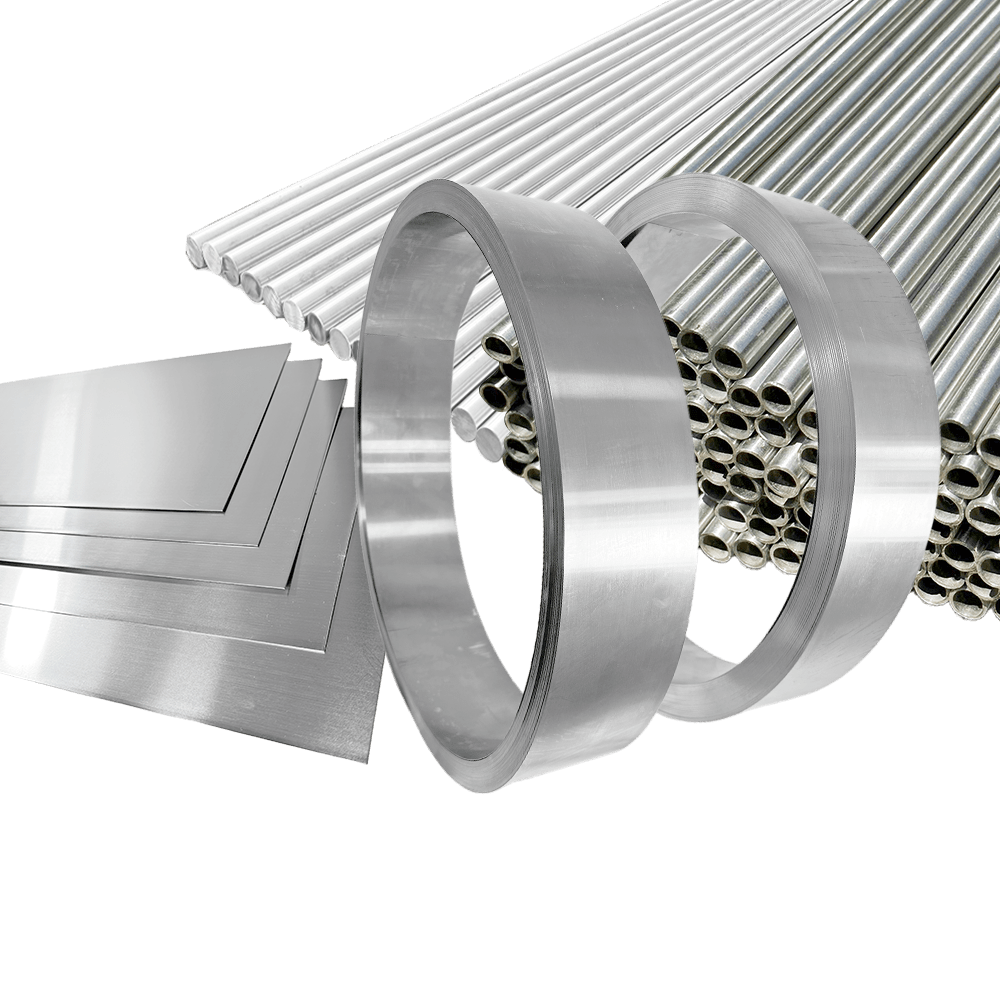

Substrate shape: wire/strip/rod/pipe/plate

Alloy series: nickel-chromium alloy

Implementation standards: YB/T5243, GOST

Application fields: industrial field, aerospace, military industry, marine ships