Brand: KX-Alloy

Similar grades:ЭИ602,ХН75МБГЮ

Certification certificate:ISO9001:2015

Place of Origin: Danyang, Jiangsu, China

Alloy Category: High Temperature Alloy

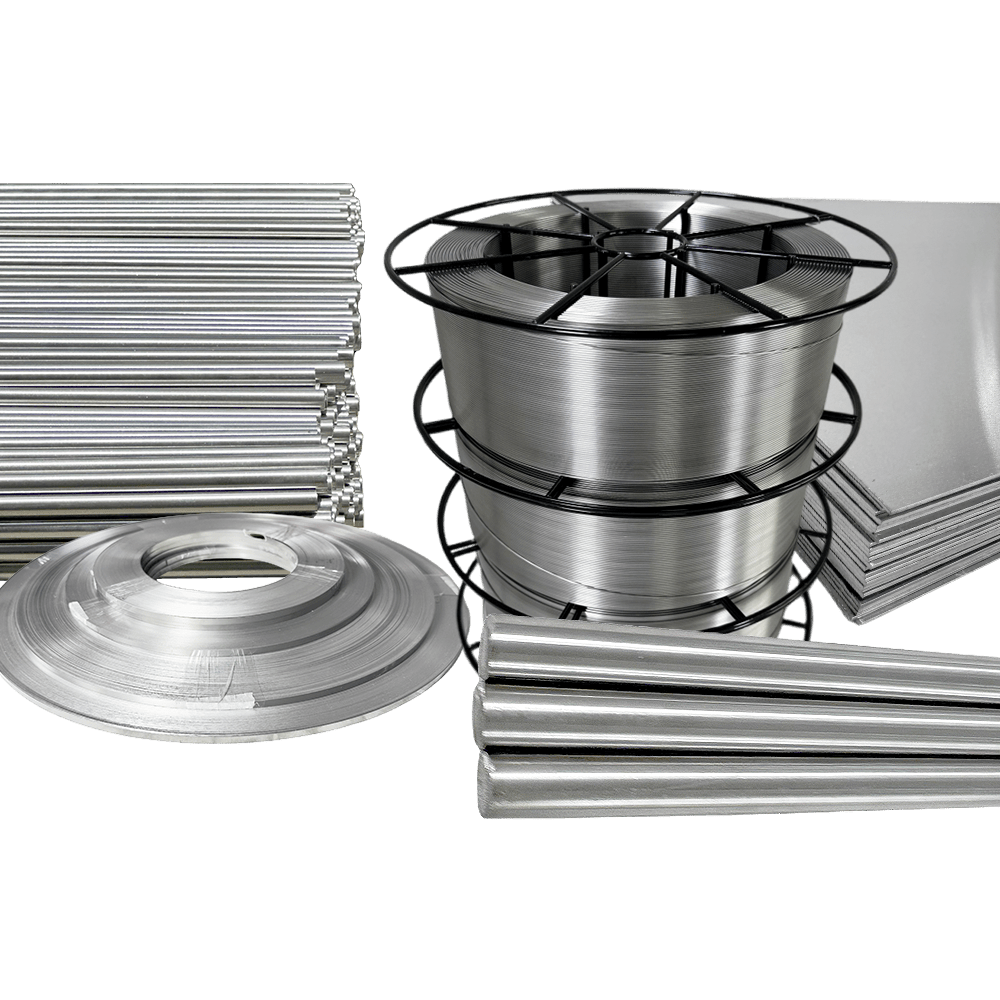

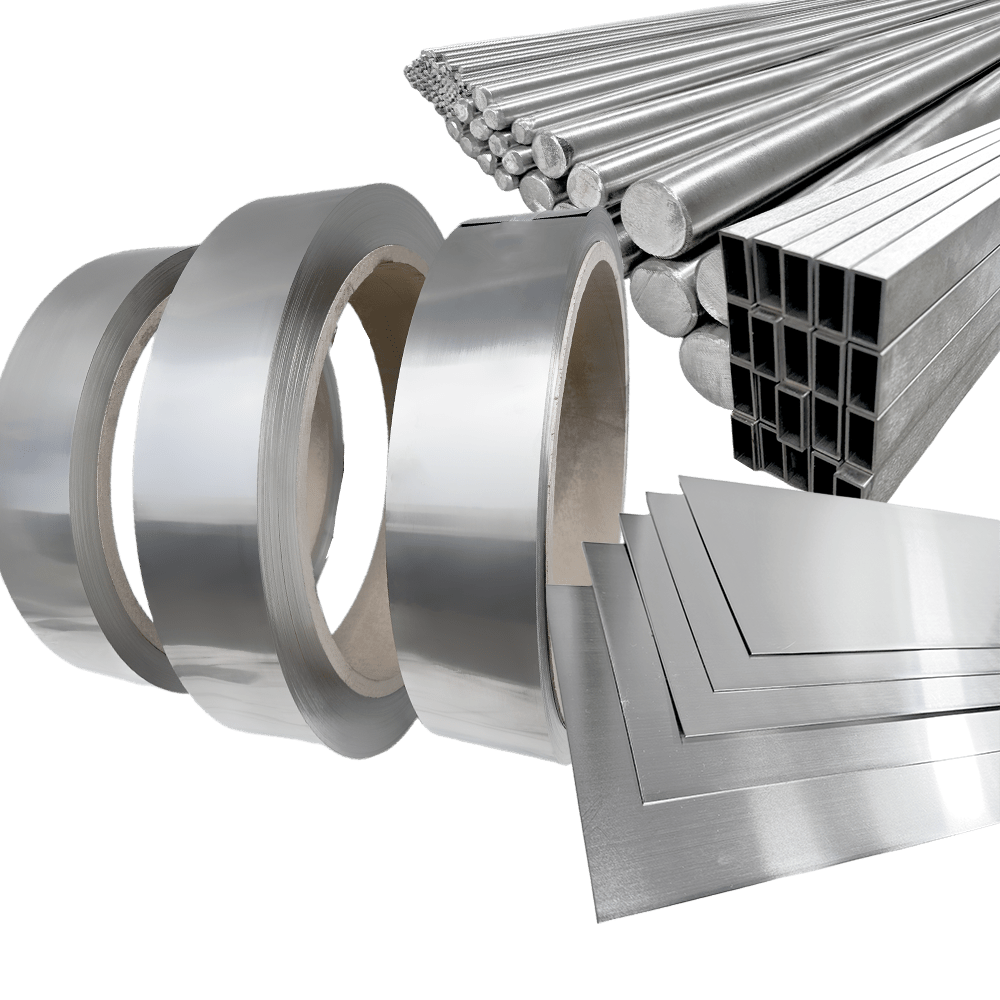

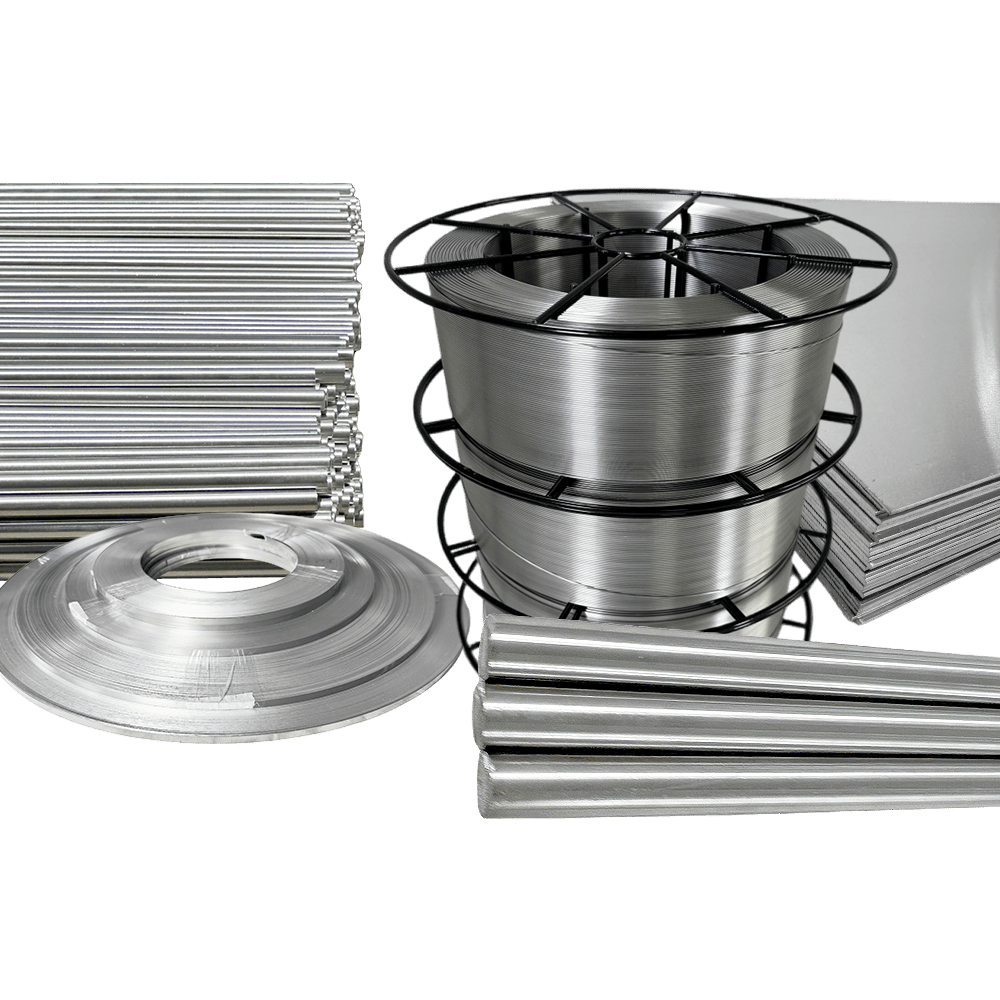

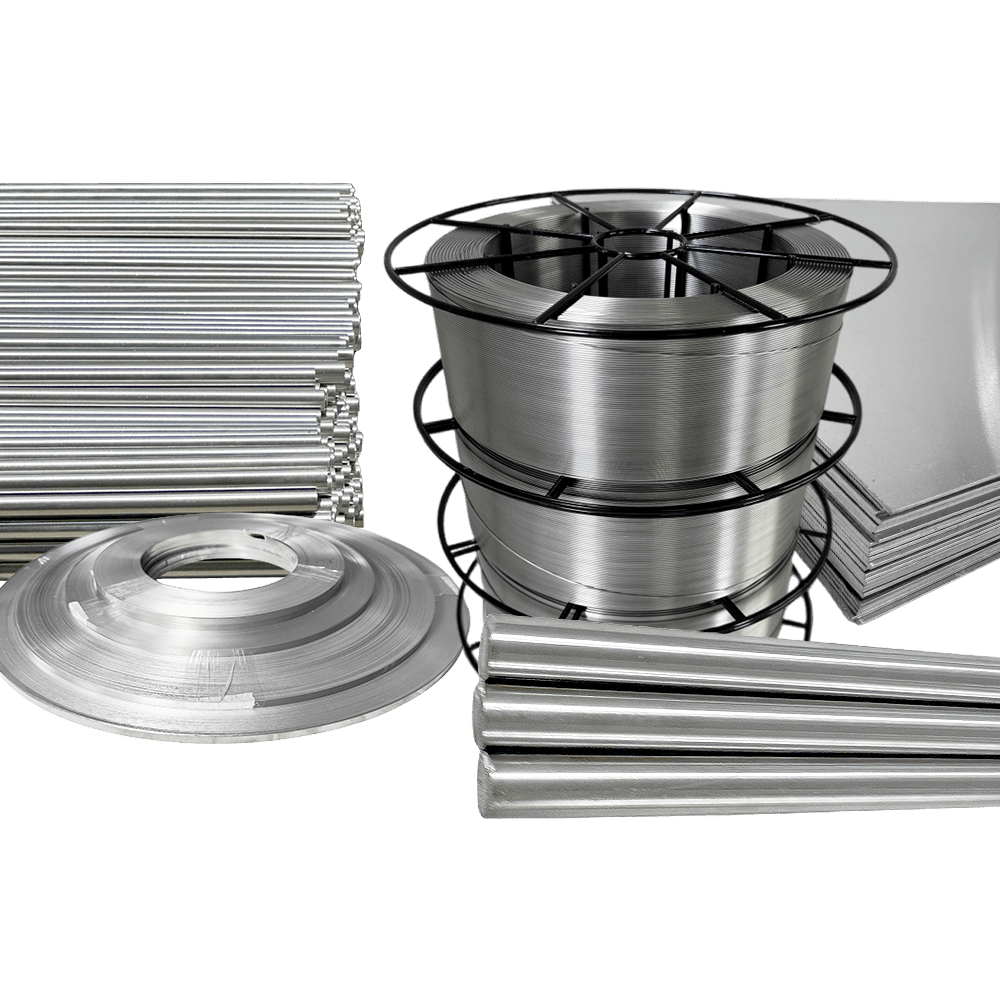

Substrate shape:wire/strip/bar/pipe/plate

Alloy series: nickel-chromium alloy

Implementation standards:GB/T 14992

Application areas:aerospace