Brand: KX-Alloy

Similar grades:Inconel X-750,NiCr15Fe7TiAl,NC15FeTNbA,ATGF,NCF750

Certification certificate:ISO9001:2015

Place of Origin: Danyang, Jiangsu, China

Alloy Category: High Temperature Alloy

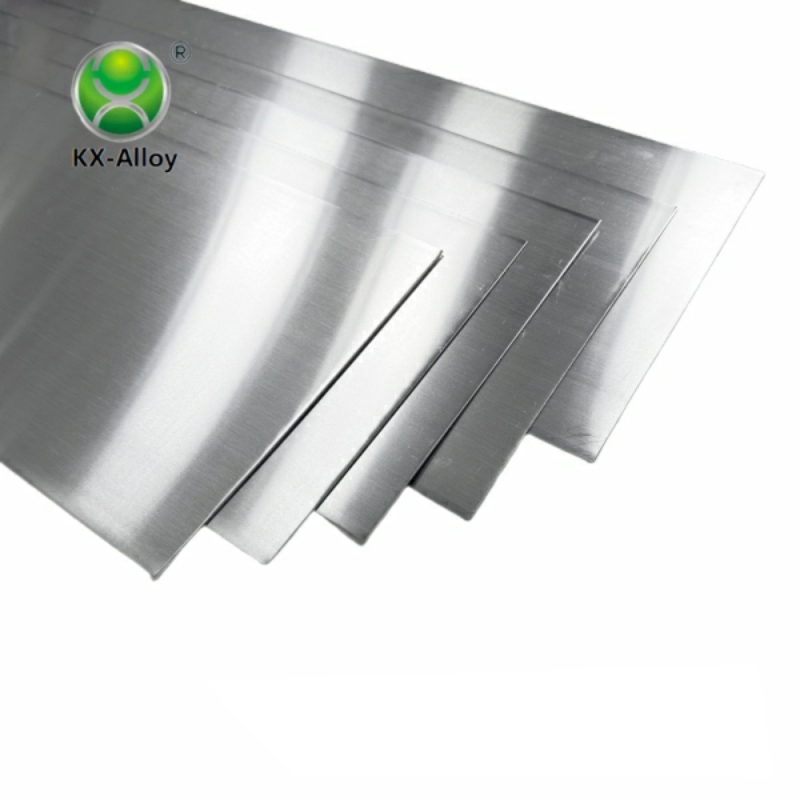

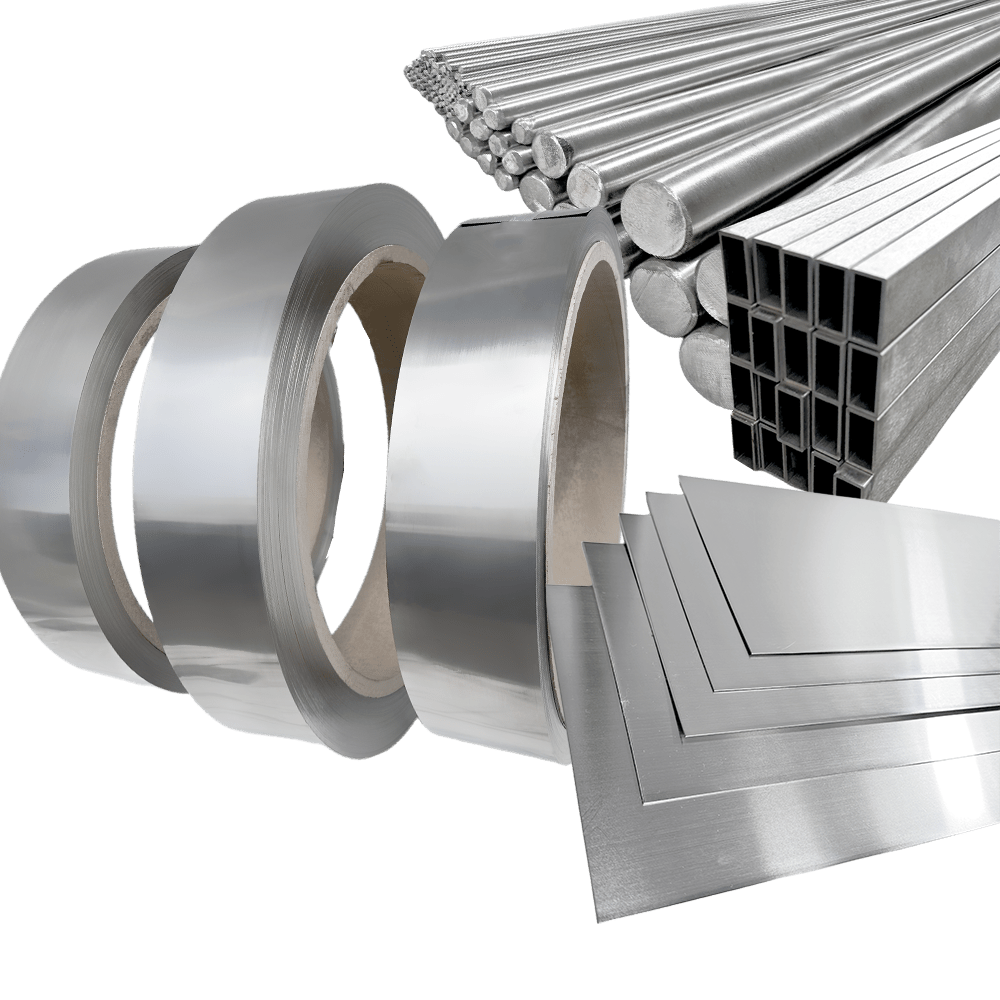

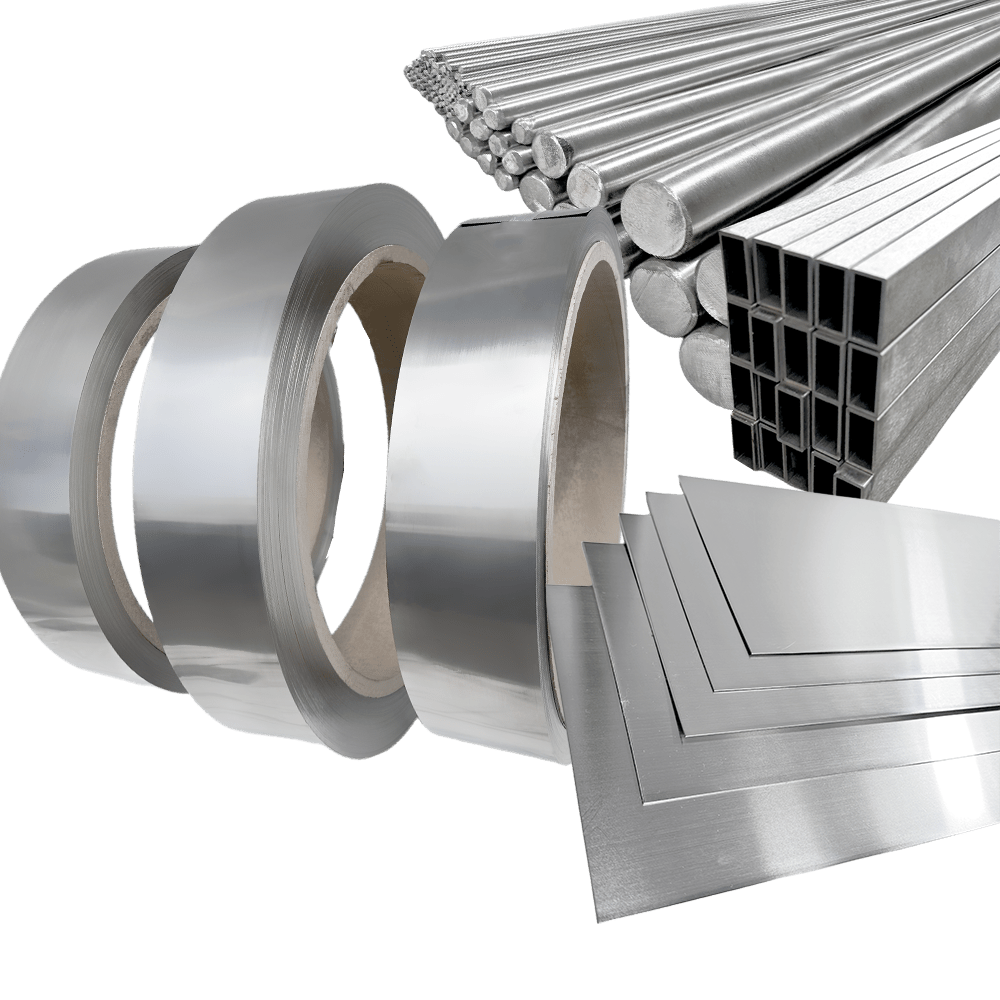

Substrate shape:wire/strip/bar/pipe/plate

Alloy series:nickel-chromium-iron alloy

Implementation standards:GB/T 14992

Application areas:aerospace, industrial sector