Danyang Kaixin Alloy Material Co., Ltd.

Product description and application

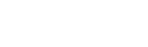

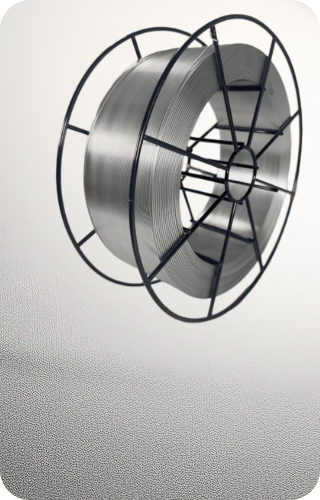

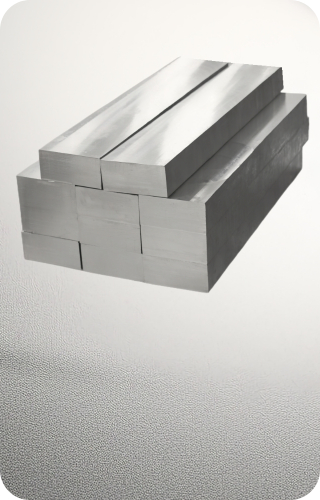

GH3600 is a Ni-Cr-Fe-based solid solution strengthened deformed high-temperature alloy. It has good thermal strength and high plasticity below 800°C, and has good high-temperature corrosion resistance and oxidation resistance below 1000°C. The alloy has a stable structure for long-term use and has excellent hot and cold processing, welding properties and low-temperature mechanical properties. Alloys can be strengthened by cold working and can be joined by resistance welding, fusion welding or brazing. It is suitable for making engine combustion chambers that operate below 700℃~800℃, and anti-oxidation parts that can withstand low loads below 1100℃. The main products include cold-rolled sheets, hot-rolled thick plates, strips, wires, bars, pipes, round cakes, ring blanks and ring forgings, etc.

GH3600 has been used to make rocket engine nozzle extensions, aircraft engine high-pressure compressors, stationary inner and outer rings, high-pressure guide blade orifice plates, sealing sheets, etc. It is also used to make exhaust pipes, carburizing containers, heat treatment equipment rollers, springs, heat exchanger pipes, reactor control rods and pipes in the fields of petrochemical industry, nuclear reactors, chemical food equipment and electronic components.

GH3600 has good corrosion resistance in fresh water and flowing seawater. In still seawater, corrosion spots may occur. It has high corrosion resistance to various exhaust gases, alkaline solutions and most organic acids and compounds. It is not easy to produce stress corrosion cracking caused by chloride ions, but it is easy to produce stress corrosion cracking under conditions of high concentration of caustic alkali or high temperature mercury.