Brand: KX-Alloy

Approximate grade: SNi6686 NiCr21Mo16W4

Certification certificate: ISO9001:2015

Place of Origin: Danyang, Jiangsu, China

Alloy Category: Corrosion Resistant Alloy

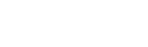

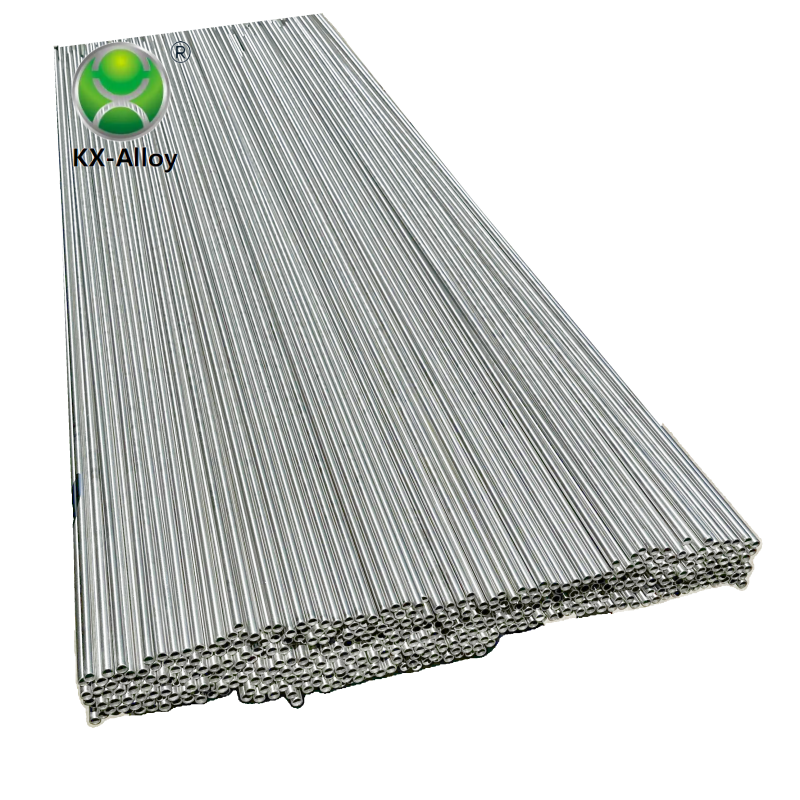

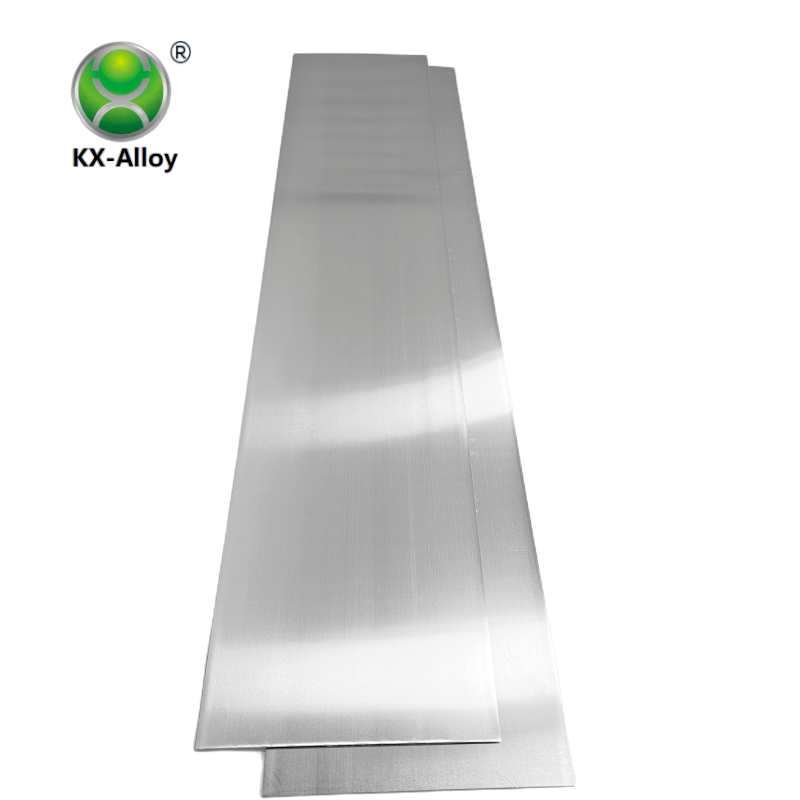

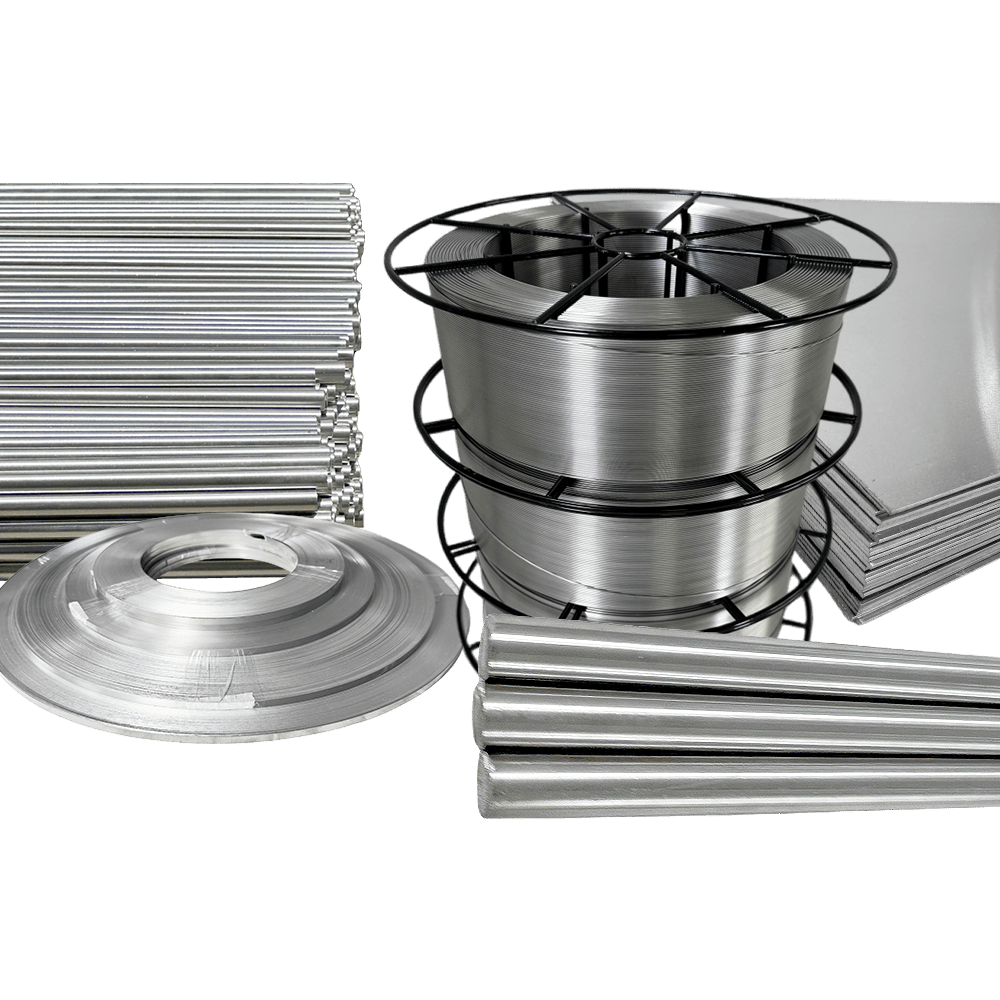

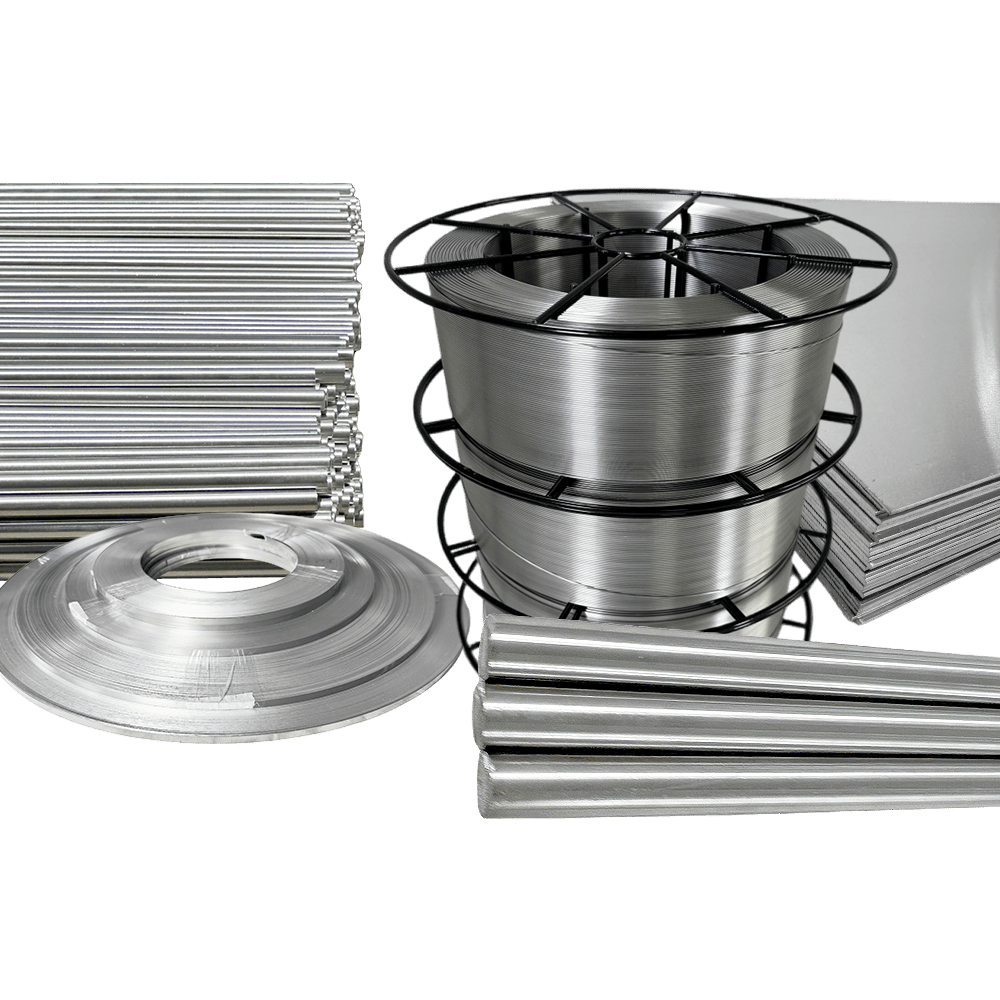

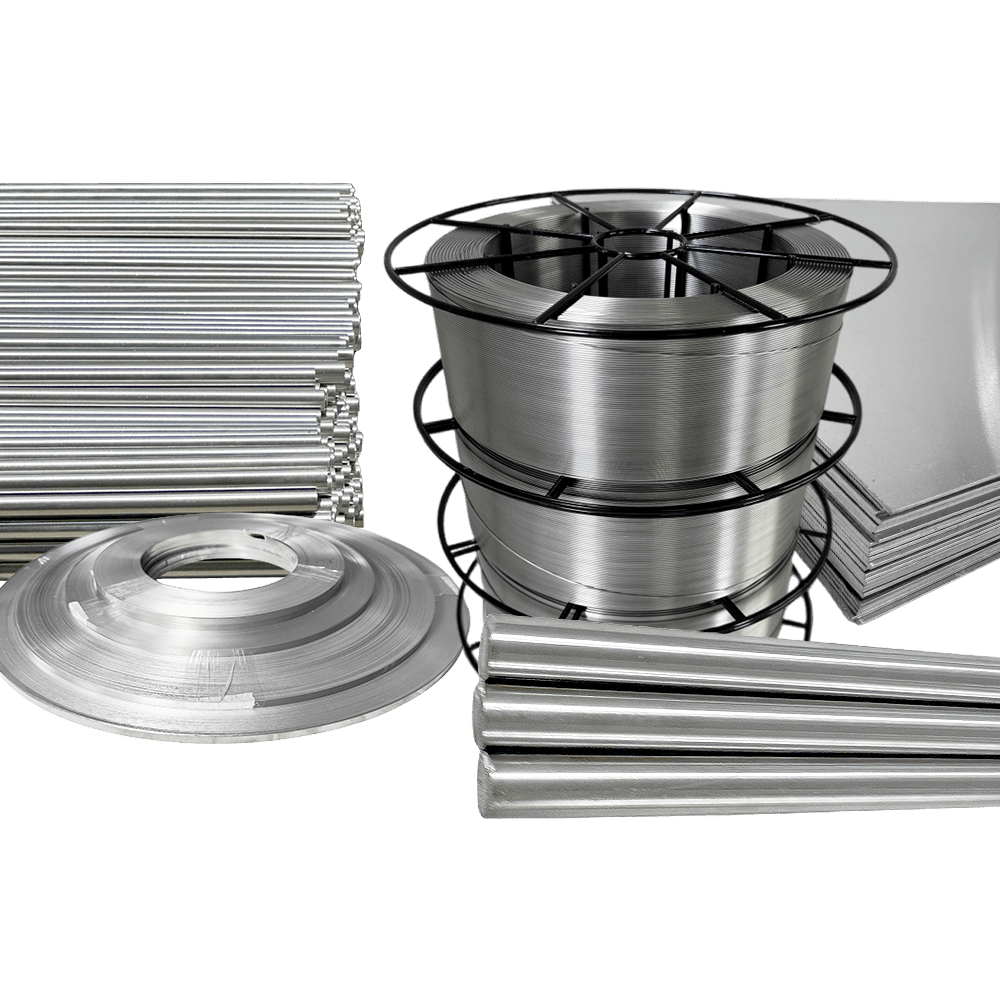

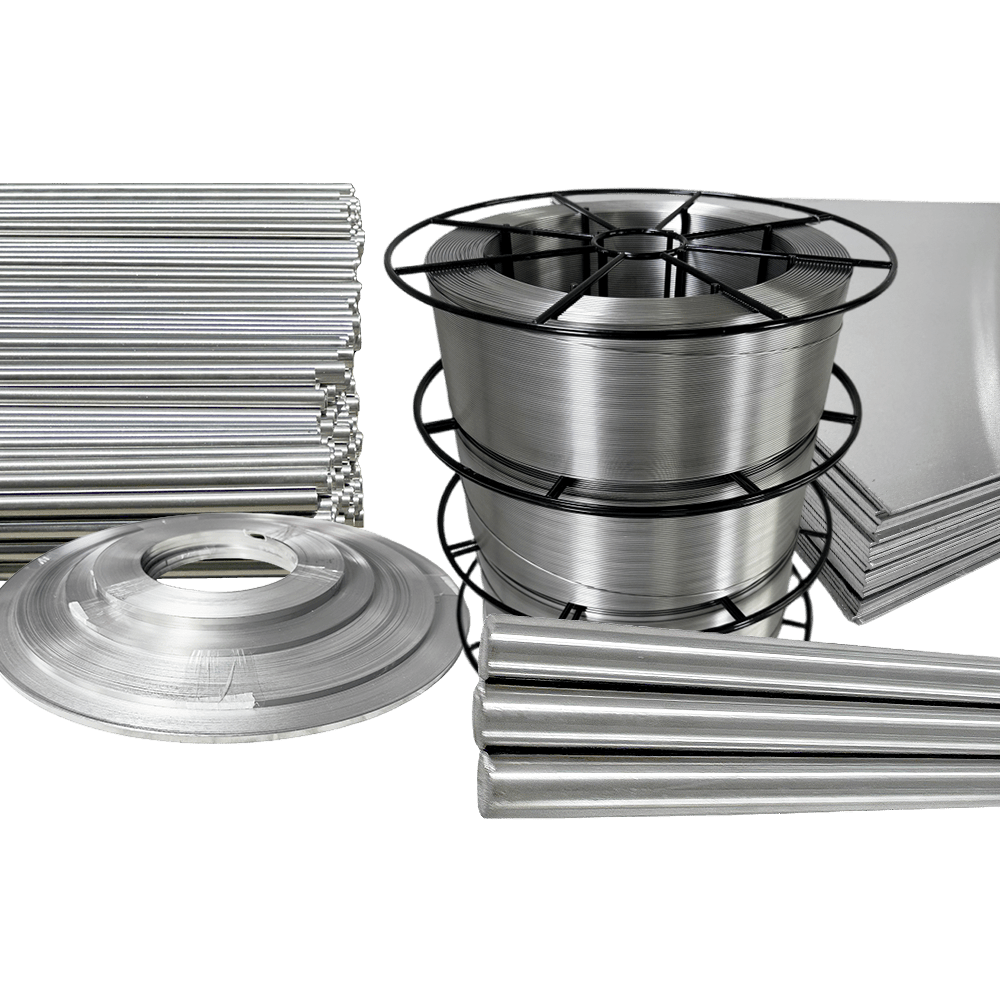

Substrate shape: coiled wire/strip/straight strip

Alloy series: nickel-chromium-molybdenum alloy

Implementation standards: GB/T15620-2008; AWS A5.14:2005

Application fields: petrochemical industry, industrial field, energy field